Advances in software for marking design and control

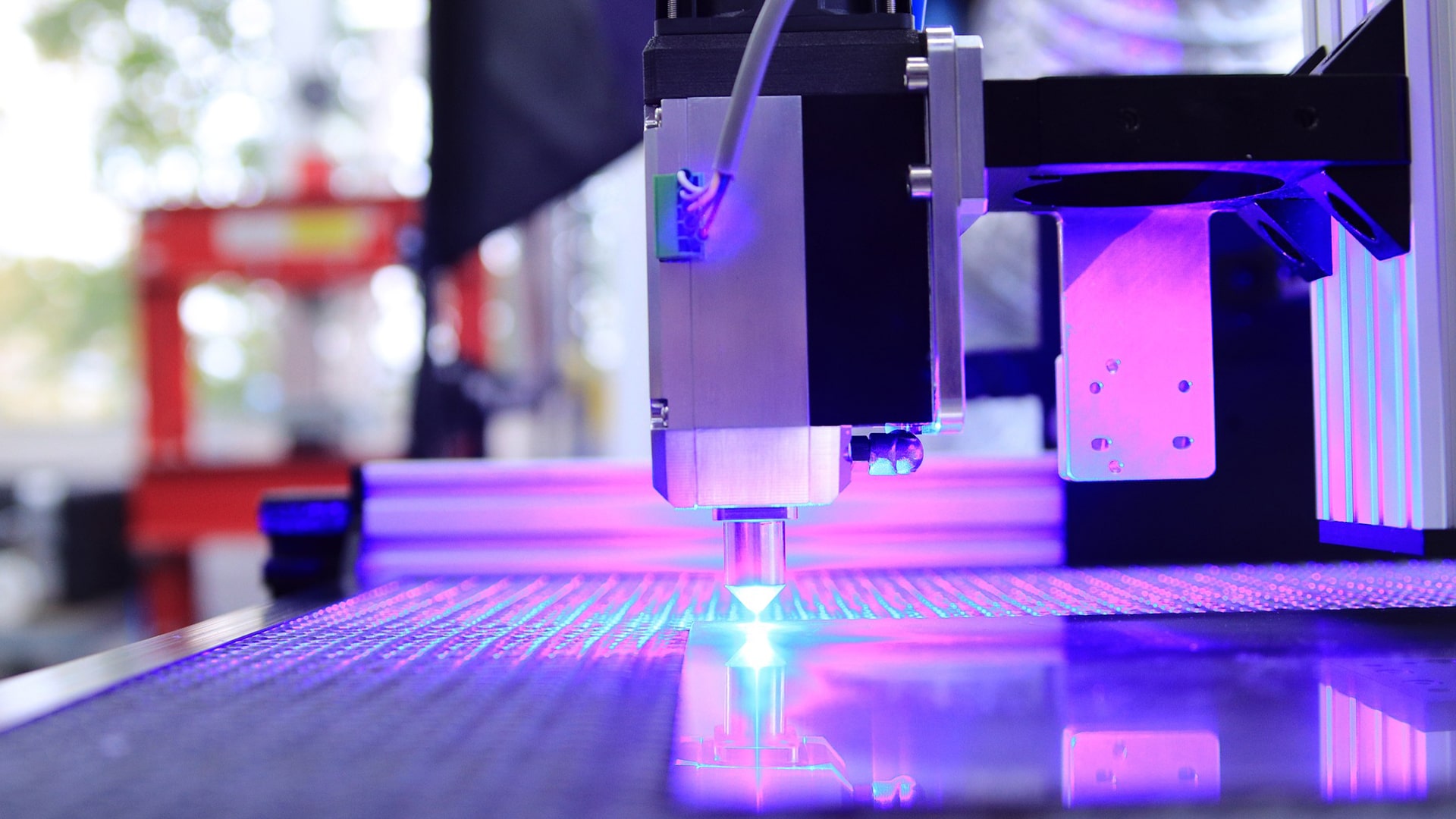

Today, technological developments in the field of industrial marking are not only limited to physical equipment, such as laser marking systems, but also to the software that manages them.

New design and control tools are transforming the way companies handle part and product marking, making it more efficient, customizable and easy to integrate into advanced production environments.

SIC Marking, a leader in industrial marking solutions, is at the forefront of these advances, offering innovative software that optimizes every step of the process.

Main functionalities of the new software software

1. Intuitive and user-friendly interfaces

New developments in marking software are designed with the user experience in mind. Intuitive graphical interfaces allow operators to set up and manage marking processes easily, saving time.

2. Automation and advanced customization

Mass customization is a growing demand in sectors such as automotive, electronics and consumer goods. Today’s software makes it possible to create unique designs for each product with a simple adjustment in parameters, facilitating customization without compromising production speed. In addition, integrated automation capabilities ensure that systems automatically adjust design and marking based on material characteristics.

3. Integration with management systems and IoT

Connectivity is a key component of modern systems. SIC Marking software enables direct integration with ERP platforms, MES and other industrial management tools, ensuring a continuous flow of information. In addition, being IoT-ready, marking systems can be connected to smart grids, providing real-time data on marking quality and status.

Benefits for companies

Thanks to all these advances, companies can:

- Reduce setup time and minimize and minimize production interruptions.

- Increase marking accuracy and consistency marking, even on small parts or complex designs.

- Improve product traceability of products through unique codes that are automatically generated and marked.

- Optimize operating costs by integrating software that allows automation and predictive maintenance.

Advances in design and control software for industrial marking are redefining the standards of quality, efficiency and customization.

SIC Marking, with its commitment to innovation, offers tools that not only facilitate the marking process, but also allow companies to adapt to the demands of Industry 4.0. With these solutions, companies can stay competitive, improve their operations and offer higher quality products in a constantly evolving market.