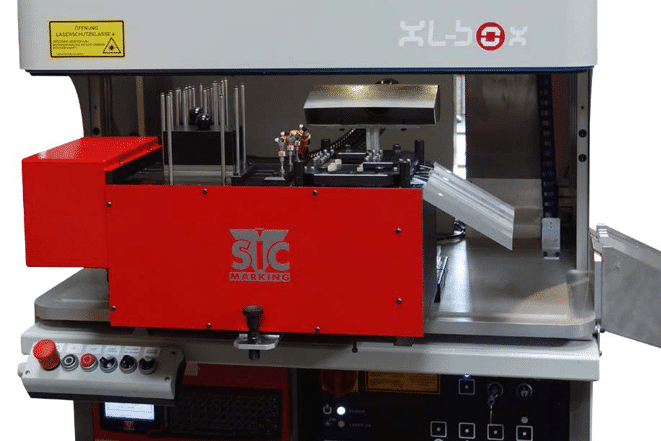

case study

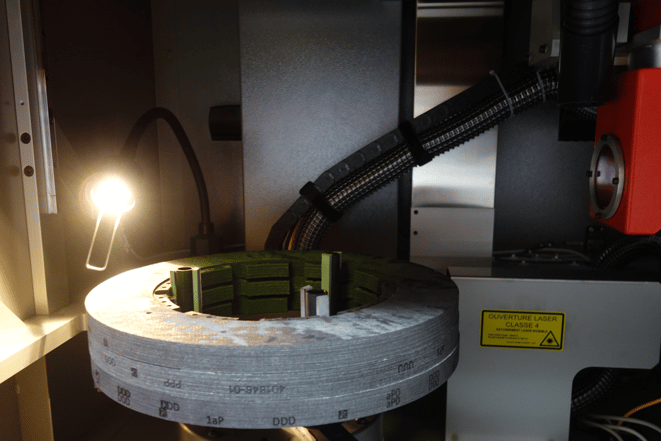

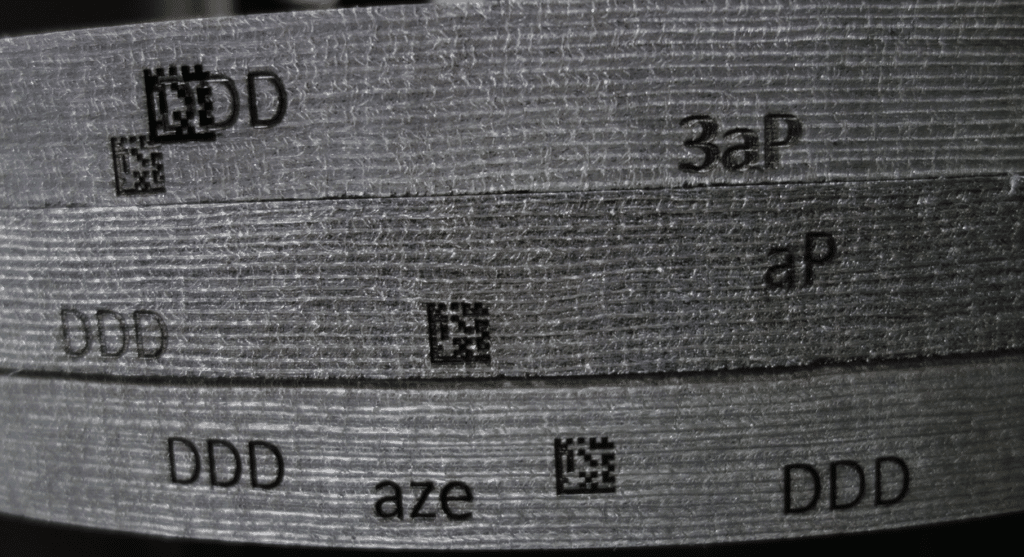

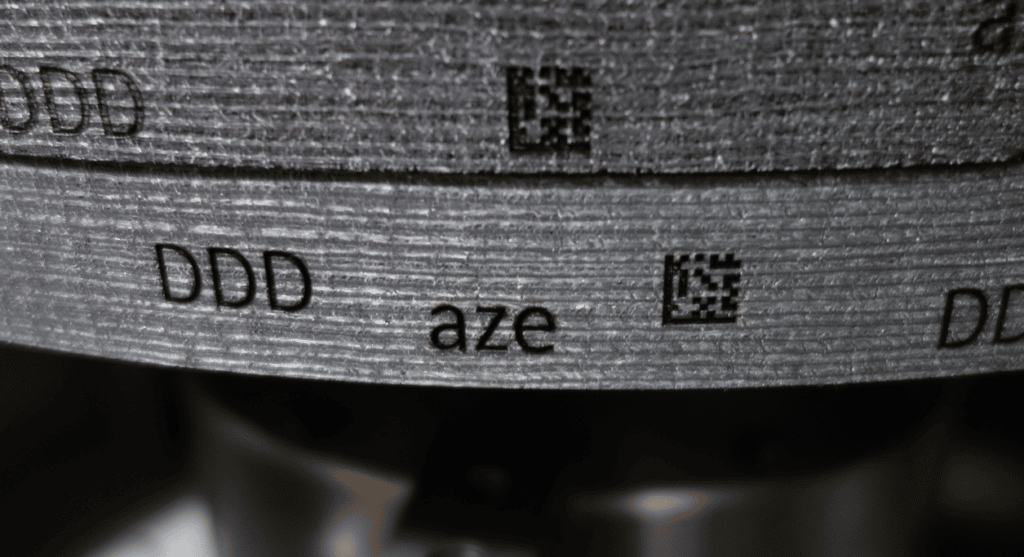

Deep Data Matrix for carbon disk brakes

An aeronautical company wanted to improve the marking of various carbon disk brake products for aircraft landing gear.

More precisely, the client wanted to replace marking by milling (alphanumeric) with laser technology and to add a Data Matrix code (alphanumeric and Data Matrix) to optimise its production process.