case study

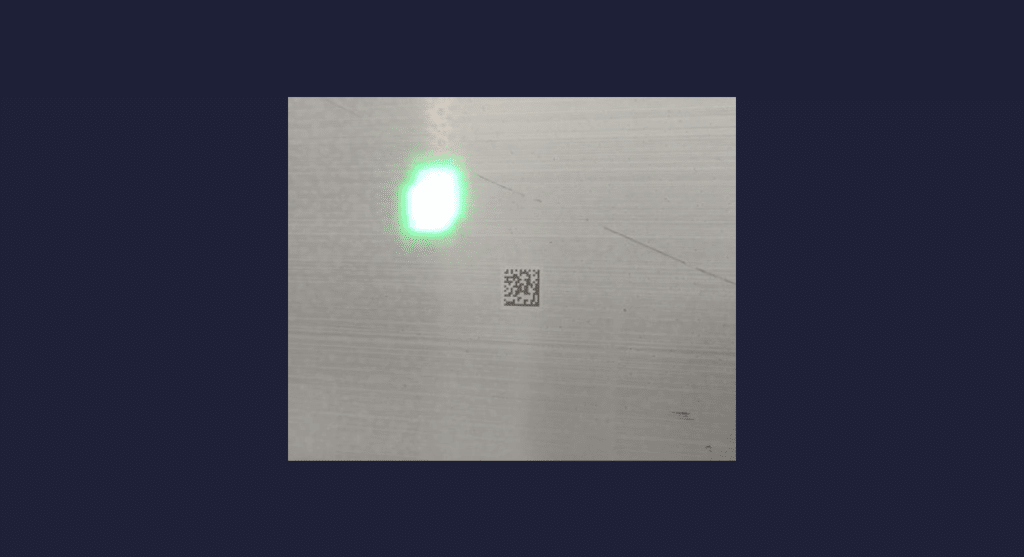

Laser marking a QR code on a motor stator

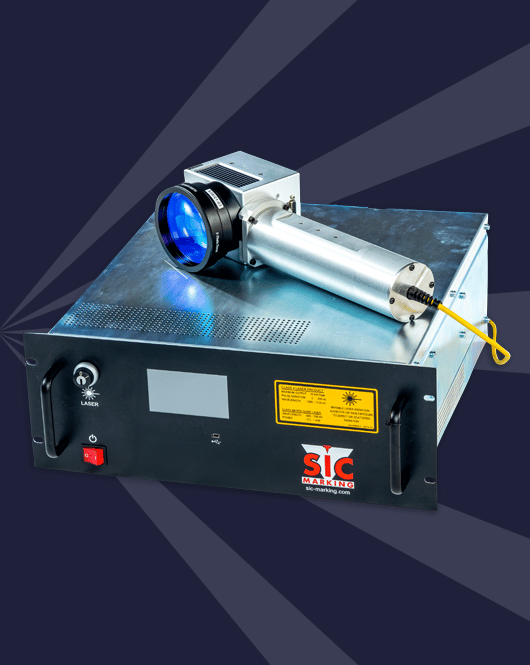

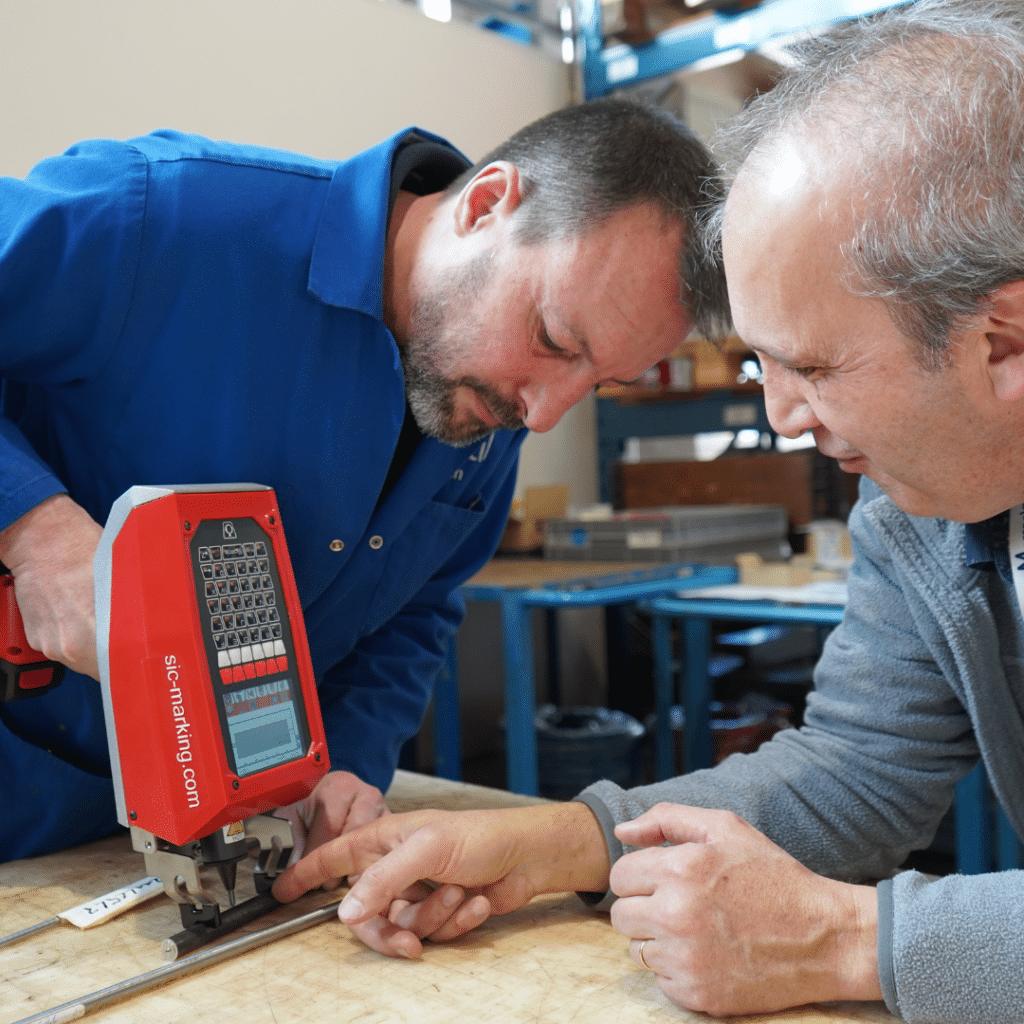

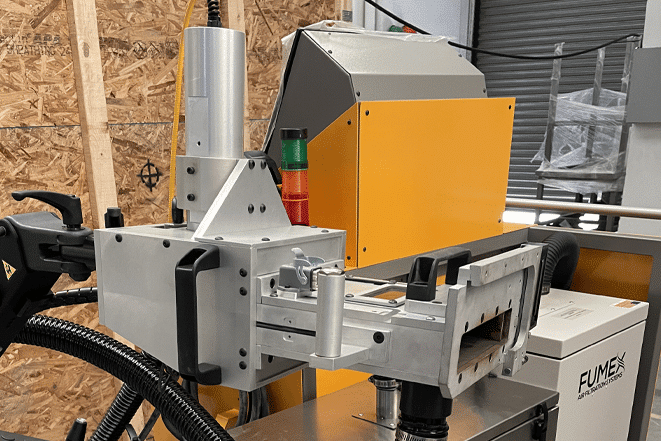

The client, an electric vehicle manufacturer, wanted to have a high-contrast Data Matrix and plain text marked on its motor stators.

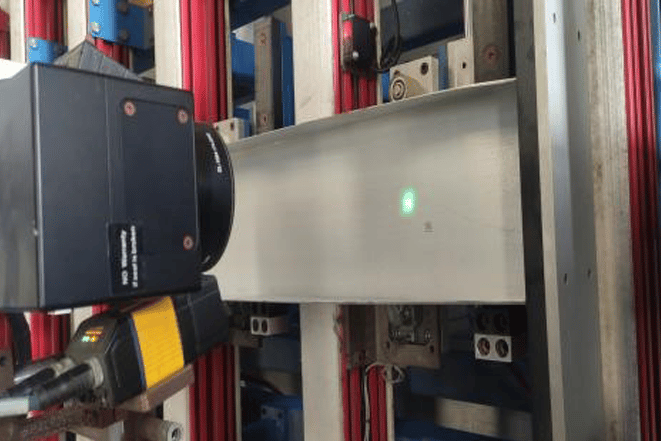

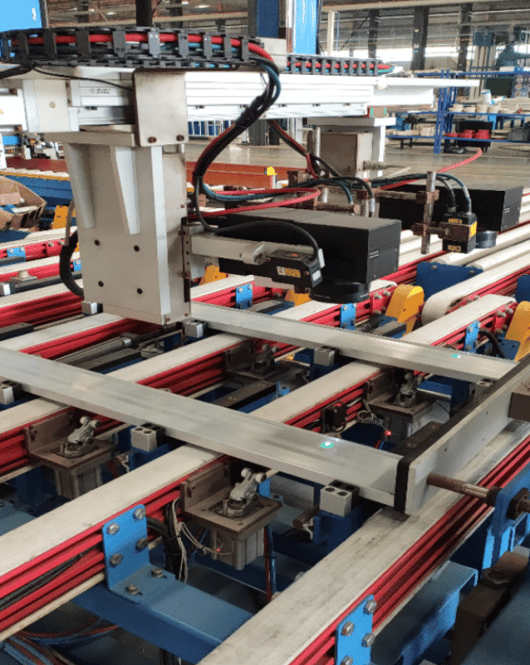

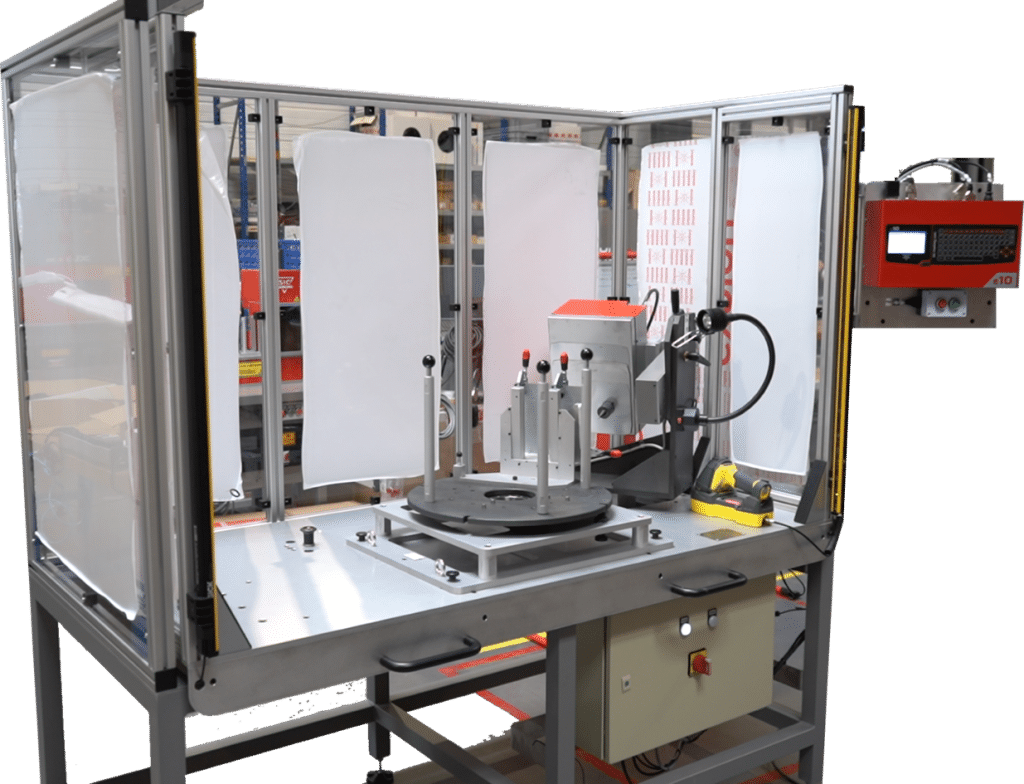

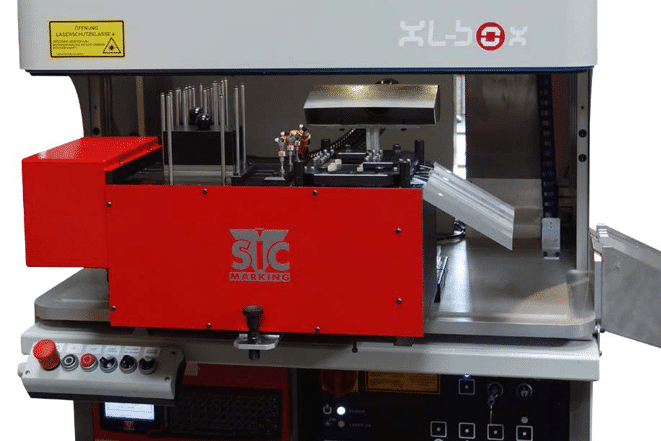

To this end, it needed a laser marking station that could be integrated into its production line.