case study

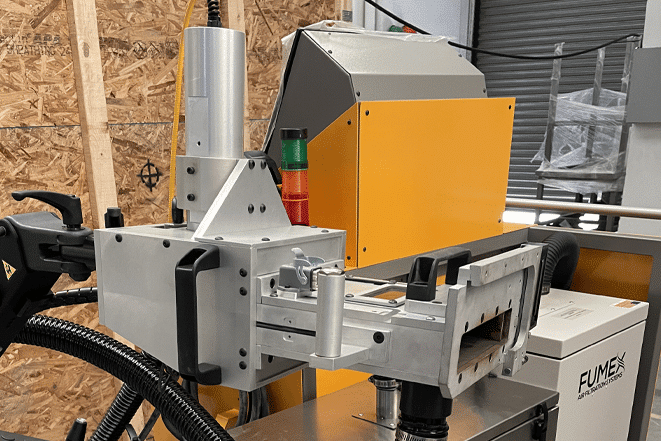

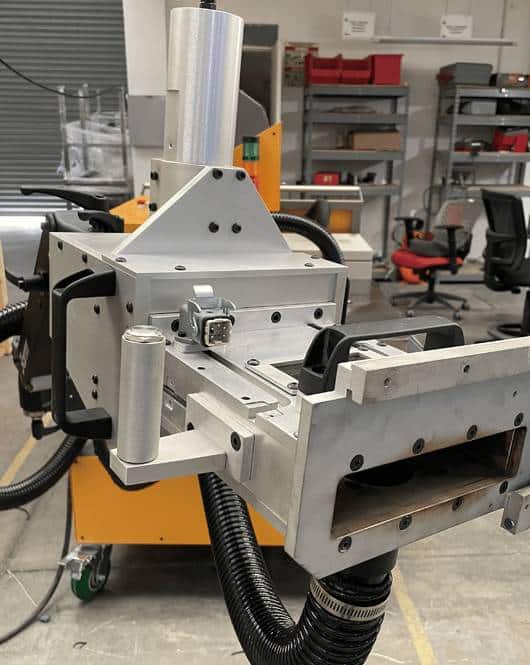

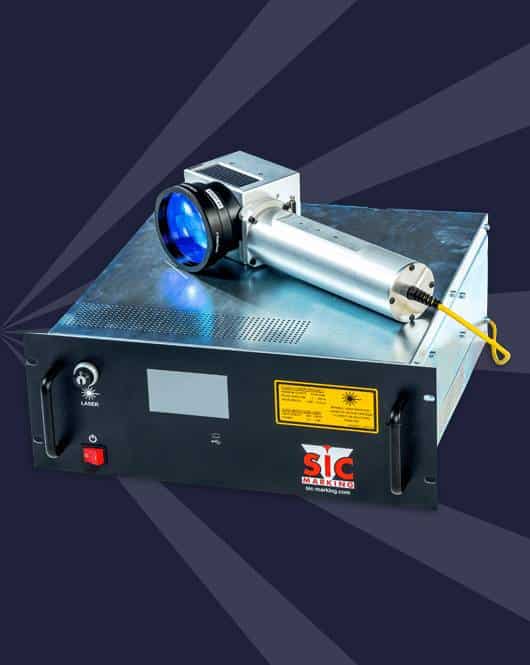

VIN laser marking

A German group, a leader in the automotive sector, makes use of SIC MARKING’s expertise for marking VIN chassis numbers on its light and heavy vehicles.

The number marked is internationally recognised by all the bodies and government departments responsible for approving and regulating vehicles.

For years, the automotive group has relied on SIC MARKING’s solutions for its flawless marking processes, which are capable of adapting to its production constraints.

The group’s requirements in terms of traceability are very stringent and, as required by the standard, markings must be robust, remain legible for the vehicle’s entire life and withstand attempts to falsify them.