Industrial marking on metals

We will analyze the characteristics and advantages of the techniques, tools and technologies used in the process of marking metal parts and we will recommend the best Sivart products to carry out this process.

Advantages and applications of industrial metal marking

Nowadays, there are more and more requirements in production traceability processes. production traceability and comprehensive quality and comprehensive quality controls, especially in many of the mass-producing industrial sectors.

This requires the manufacturer to identify and locate its merchandise very precisely, so the coding of its products is vital, as it allows total control of production. Some of the benefits of industrial marking are:

- Standardization of products, as well as their identification of production details (name, machine used for production, serial number, production date, batch).

- It gives the possibility to track and know the status of the part in real time and where it is in the production process.

- Control and identify faults and counterfeits quickly and, consequently, increase the quality of the part and production processes.

This process of coding and marking products not only brings benefits to the producer, but also has advantages for the distributor and the customer, as it allows the addition of aesthetic elements, such as customizing and engraving logos.

Specifically in sectors that produce or market metallic materials and products such as stainless steel or aluminum, marking equipment is essential. Below, you will find some examples of sectors that use metal coding.

Applications and uses of marking on metal parts

In today’s production lines, there are an enormous number of parts and elements that companies must keep an exhaustive control over . Especially in metal-intensive industries, coding technologies of this type are of vital importance.

Some of the industries that require this type of marking processes to perform their activity correctly are:

- Aerospace: in various aircraft parts and components such as seats, structures, turbines, etc.

- Metal-mechanical: in pieces such as ingots and plates.

- Electronics: integral electronic components, capacitors and final product components in washing machines, blenders, etc.

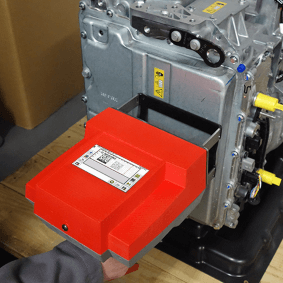

- Automotive: in a large number of vehicle parts such as bolts, pipes, plates, seats, engine parts, etc.

- Others: any industry that must mark brass, copper, titanium, stainless steel, alloys, etc. parts.

All these sectors use marking on their mechanical parts with different types of technologies. Let’s see below what are the characteristics of the best metal marking techniques and tools.

Metal marking technologies and techniques

The choice of method for marking metal parts is an important decision, as factors such as cost, process and the type of surface to be marked must be taken into account.

For this purpose, we analyze the main characteristics of the different direct-to-part metal marking technologies :

Industrial laser marking of metal parts

Marking with laser technology is one of the most widely used today, especially those of the fiber series on metal. It is a very suitable technique for processes that require the elimination of noise during marking.

Another advantage is their short cycle times. On the other hand, they require some occupational safety measures .

In you will find the most innovative technology with machinery such as the laser marker. Laser marking head 104 Easy or the L-BOX and XL-BOX laser marking machines.The L-BOX and XL-BOX laser markers are a guarantee of quality and safety for different types of sectors and industries.

Industrial marking by micro-percussion for metal parts

The micro-percussion process is characterized by marking a matrix of dots under pressure on a limited surface. Its main advantage is its low cost and its effectiveness in processes that require painting after marking.

On the other hand, this technique requires secure clamping of the part and has the disadvantage of generating noise in the marking process.

At Sivart you will find a wide range of products for micro-percussion, such as marking machines markers, column e integrated marking machines.

Industrial marking by scratching on metals

It is a technique quite similar to the previous one, the difference is the marking with a continuous stroke where the punch presses and scratches the material by compressed air. It is especially recommended when it is required to mark the Vehicle Identification Number (VIN). On the other hand, it has the disadvantage of not being able to generate 2D codes.

At Sivart we have available scratch marking machines such as the I63S – I124S.

Contact us without obligation and the Sivart team will advise you to offer you the best solution for your company and your sector.