Laser marking in refrigeration equipment manufacturing

In the refrigeration equipment manufacturing industry, quality and precision are paramount, for this reason, laser marking has emerged as a key technology to optimize processes and ensure traceability of different components. In this article, we will show you how laser marking has transformed refrigeration equipment manufacturing, highlighting the key benefits that drive efficiency and excellence in this industry.

The importance of laser marking in the refrigeration industry

Refrigeration equipment manufacturing comprises a wide range of components, from compressors to heat exchangers, each with unique specifications and functions. Laser marking has become a critical tool in this environment, providing clear and durable identification of each component.

Key benefits of laser marking in the refrigeration industry

High durability in extreme conditions

Refrigeration equipment is often located in demanding environments, either in extremely low temperatures or in humid conditions. Laser marking offers exceptional durability, resisting corrosion and wear, ensuring that component identification remains legible over time.

Improved traceability

Component traceability is vital in the manufacture of refrigeration equipment, where quality and safety are priorities. Laser marking allows the insertion of barcodes, Datamatrix, QR and other unique identifiers that facilitate tracking from production to installation.

3. Efficient customization

In the refrigeration industry, where specifications can vary from model to model and application to application, the ability to customize is a plus. Laser marking allows the creation of unique identifiers and the inclusion of detailed information, adapting to the specific needs of each component.

4. Simplified regulatory compliance

Regulations and standards in the refrigeration industry are by necessity strict. The technology of Laser marking facilitates regulatory compliance by providing clear and complete identifications of each component, which is essential for audits and certifications.

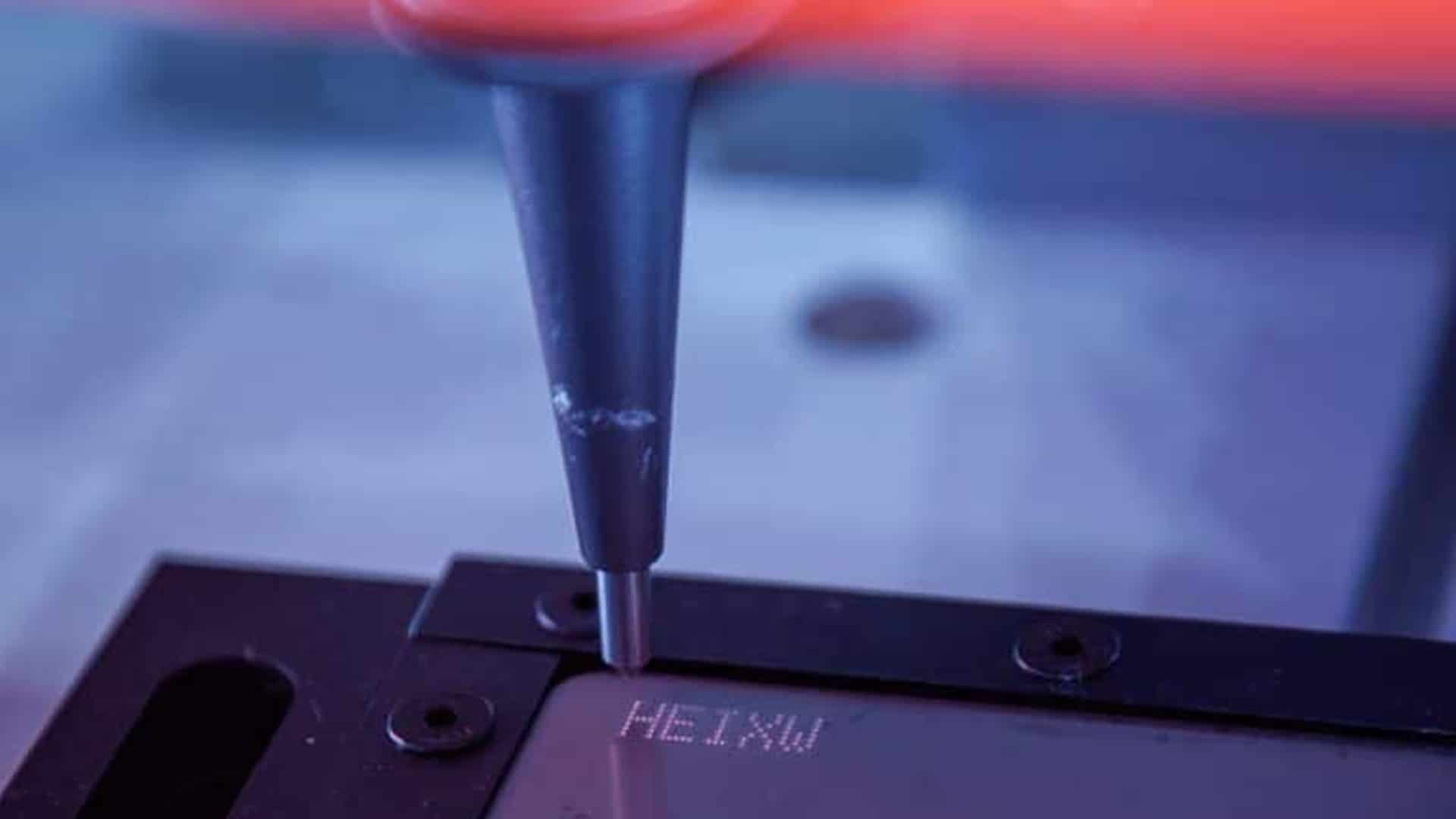

Laser marking applications in refrigeration equipment manufacturing

Refrigeration equipment has a large number of elements, for this reason, we name some of the most important applications that laser marking can offer:

Identification of compressors and motors

Laser marking allows precise identification of compressors and motors, indicating crucial information such as capacity, efficiency or date of manufacture.

2. Coding of heat exchangers

Heat exchangers, fundamental in refrigeration systems, benefit from barcodes, Datamatrix and QR for efficient traceability, ensuring optimum performance.

3. Labeling of electronic control systems

In the manufacture of modern refrigeration systems, laser marking is used to label electronic systems, facilitating their installation and maintenance.

4. Customization of parts

Specific components, such as valves and sensors, can be customized with laser marking to indicate specific functions and ensure correct installation.

Practical implementation of laser marking on refrigeration equipment

The implementation of laser marking in the manufacture of refrigeration equipment is a comprehensive process involving:

- Technology Selection: Choosing the most appropriate type of laser marking for specific needs, whether CO2, fiber or UV.

- Identifier Design: Create unique identifiers and codes containing key information such as serial numbers, manufacturing dates and technical specifications.

- Production Line Integration: Incorporate laser marking efficiently into the production line to ensure accurate and correct identification.

- Quality Verification: Implement quality verification systems to ensure that marking is always legible and meets all established standards.

Laser marking SIC Marking on refrigeration equipment

Laser marking has revolutionized the manufacture of refrigeration equipment, offering operational efficiency, improved traceability and durable identification. In an industry where innovation and quality are paramount, laser marking is presented as an essential tool to ensure the performance and reliability of the refrigeration systems we use in our daily lives. At SIC Marking we offer all kinds of marking and traceability solutions, guaranteeing quality and assurance in your industrial processes. Contact us with any questions and we will be happy to assist you!