Marking technologies in the era of Industry 4.0

Integration of marking systems with IoT and smart production management systems

Today, the move towards Industry 4.0 is radically transforming manufacturing, integrating digital technologies with industrial processes to improve efficiency, traceability and quality control. In this context, marking technologies, such as laser marking, play an essential role in creating an interconnected and intelligent production ecosystem.

SIC Markinga leader in industrial marking solutions, is positioned at the forefront of this technological revolution, developing systems that not only guarantee marking accuracy and durability, but also integrate seamlessly with the Internet of Things (IoT) and intelligent production management systems.

In this article, we will explore how these technologies are revolutionizing industrial marking and product traceability in the era of Industry 4.0.

The role of marking in Industry 4.0

Industry 4.0, also known as the fourth industrial revolution, is characterized by the adoption of advanced technologies, such as automation, artificial intelligence (AI) and IoT, to optimize and connect all aspects of production. In this environment, the marking of products, components and parts becomes crucially important, not only as a method of identification, but also as a means of ensuring traceability and real-time control of the supply chain.

SIC Marking’s laser marking solutions enable detailed information such as QR codes, barcodes, serial numbers and product-specific data to be engraved directly on parts, quickly, accurately and permanently. This information is key to tracking products throughout their life cycle, from production to final delivery, and even during after-sales service.

Integration of marking with IoT

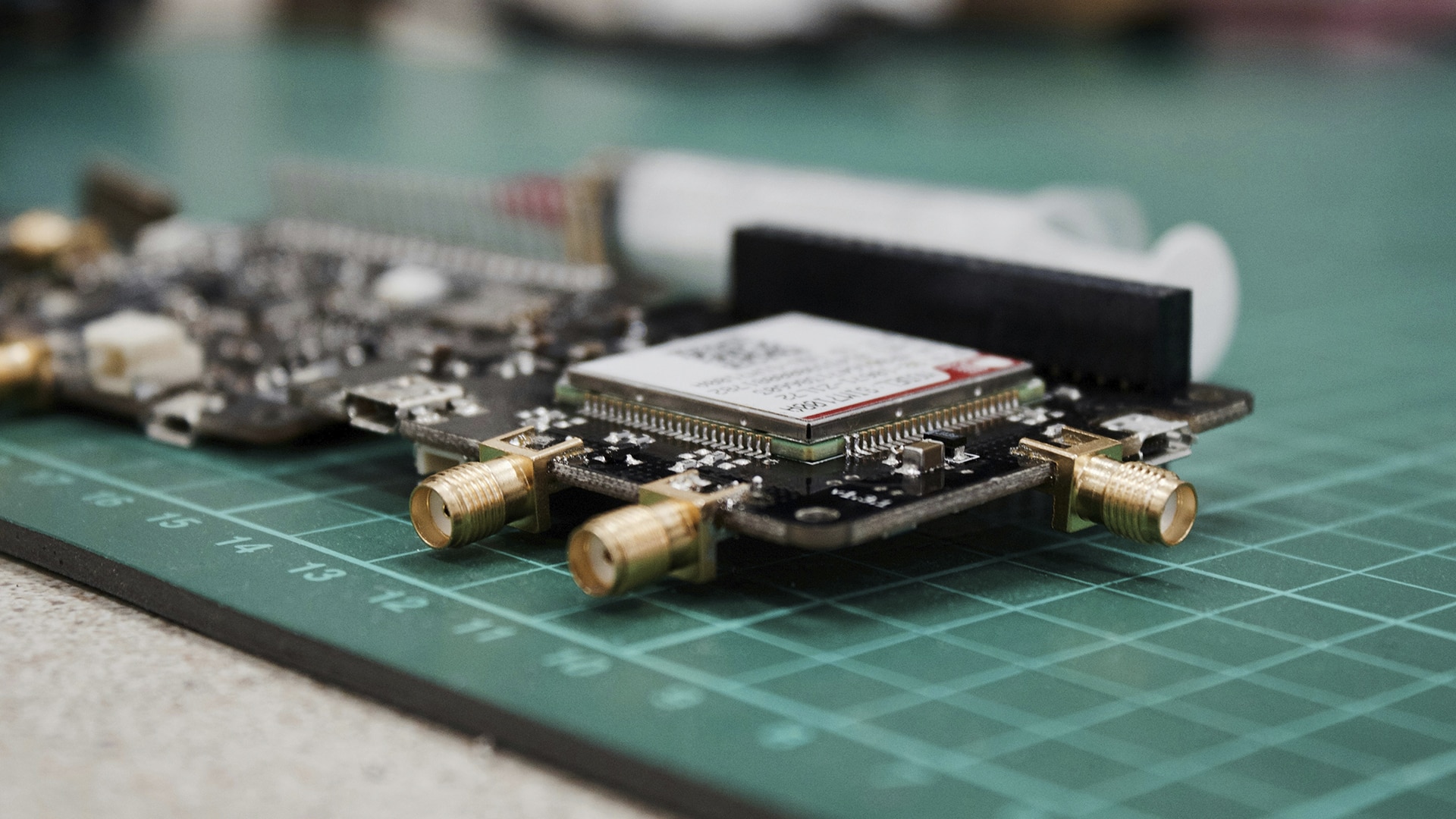

The integration of marking technologies with IoT is one of the most significant developments in Industry 4.0. The IoT allows the interconnection of machines, sensors and systems through a network, facilitating communication and data exchange in real time. In this context, SIC Marking’s marking systems are designed to be compatible with IoT platforms, enabling a continuous flow of information between marking equipment and other production systems.

For example, a laser marking system can be connected to an IoT network to receive data about the production batch, marking parameters and process settings. Once the part is marked, the system can automatically send the marking data, such as the generated QR code, to a centralized data management system. This information can be used to update inventory status, verify product quality or even trigger automatic processes in other parts of the production line.

Intelligent production management systems

Intelligent production management systems (MES) are a fundamental part of Industry 4.0, as they enable real-time monitoring and control of manufacturing processes. These systems collect and analyze data from multiple sources, including marking machines, to optimize production, reduce downtime and improve end-product quality.

By integrating SIC Marking’s marking systems with an MES, companies can gain complete visibility into their production operations. For example, if an MES system detects an error in the marking process, it can immediately adjust marking parameters or even stop production to avoid costly errors. In addition, by having all data centralized, it is possible to perform predictive analysis, anticipating failures before they occur and improving overall process efficiency.

Benefits of integrating marking systems in Industry 4.0

The integration of marking technologies with IoT and intelligent production management systems offers multiple benefits for manufacturing companies:

- Improved traceability. The ability to trace each component throughout the entire supply chain, from raw material to finished product, enables complete traceability. This not only improves transparency, but also facilitates faster and more efficient error detection and correction.

- Production optimization. Automating data exchange between marking systems and other production equipment reduces downtime and minimizes human error. Systems can be automatically adjusted in real time, ensuring a smoother and more efficient production process.

- Consistent quality. Integration with MES systems allows continuous monitoring of marking quality, ensuring that each part meets the specified standards. In case of deviations, the necessary adjustments can be made immediately, avoiding the production of defective batches.

- Cost reduction. By improving efficiency and reducing errors, companies can significantly reduce operating costs. In addition, the ability to perform predictive maintenance based on data collected in real time reduces costs associated with unplanned downtime.

Conclusion

In the era of Industry 4.0, marking technologies are rapidly evolving to meet the needs of an increasingly digitized and interconnected production environment.

SIC Markingwith its commitment to innovation and quality, offers marking solutions that not only meet the highest standards of precision and durability, but also integrate seamlessly with IoT and intelligent production management systems.

By adopting these technologies, companies not only improve their ability to track and manage their products, but also position themselves to compete effectively in an increasingly demanding global marketplace. The integration of marking systems into Industry 4.0 is undoubtedly a crucial step towards the future of smart and efficient manufacturing.