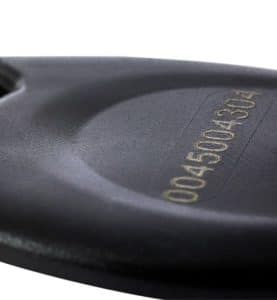

There is a wide variety of plastics, the choice of marking technology depends on the type of plastic and also on all the additives/pigments contained in the plastics.

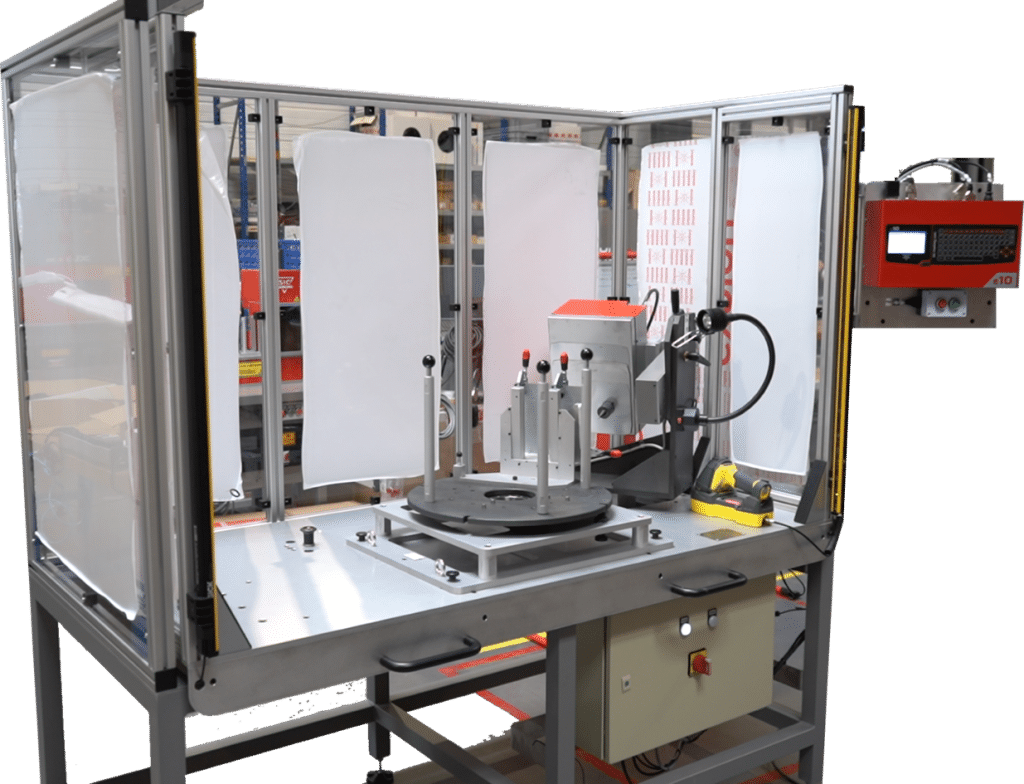

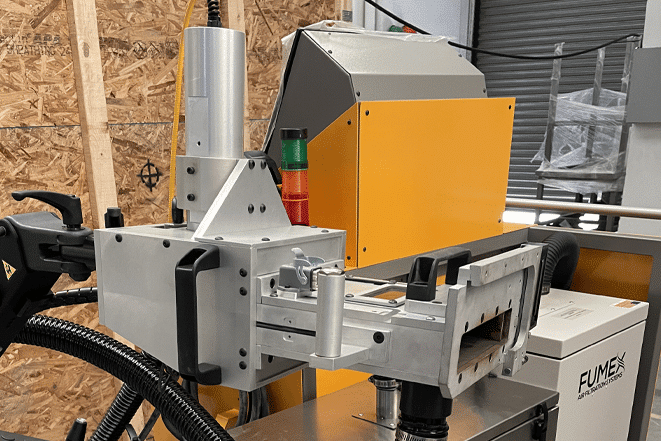

Each project is unique and the richness of the SIC MARKING offer makes it possible to identify the marking machine that will give the best results, in dot peen technology, fibre laser marking (in particular HD because it limits the heating of the material) or green laser.

The great variability in the composition of the plastics requires a testing phase.

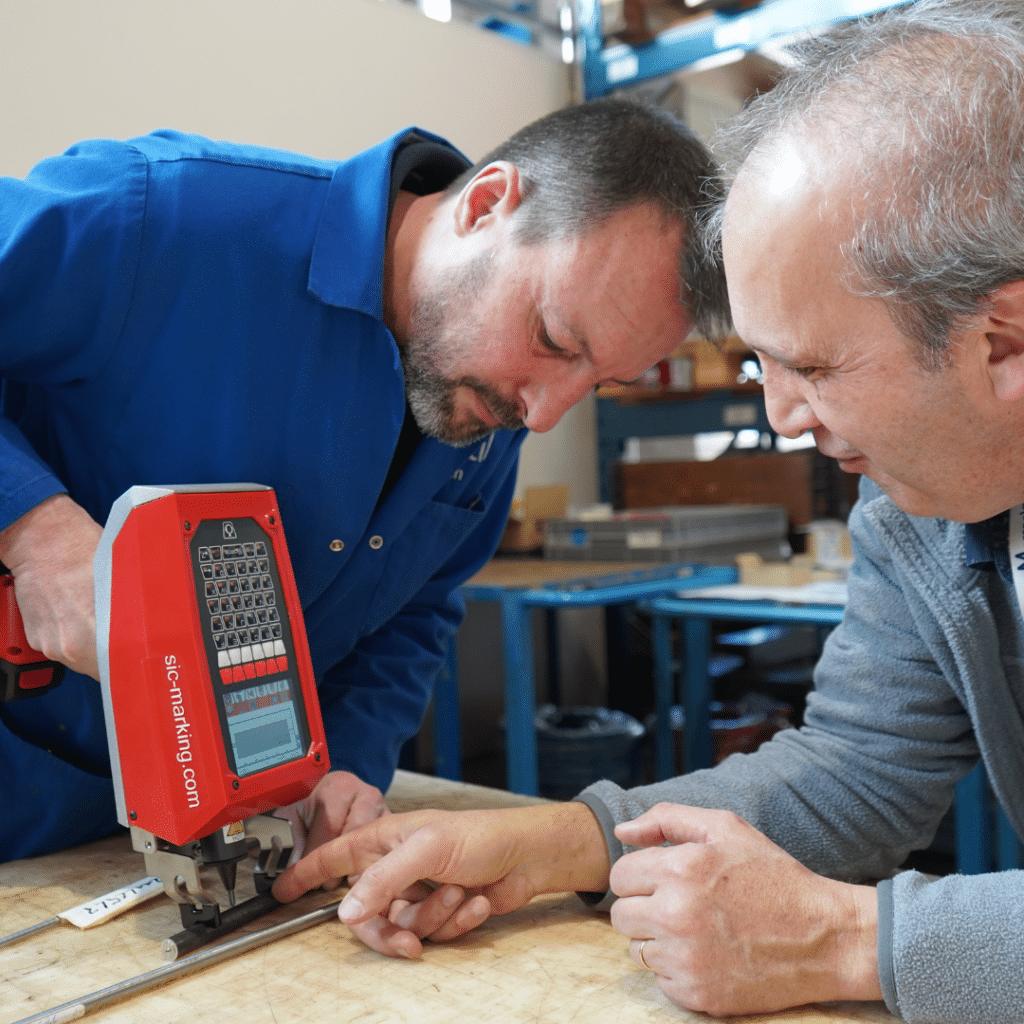

SIC MARKING has developed Centres of Excellence to serve your projects.

Our experts conduct tests, free of charge, to identify the SIC MARKING solution that will give the best marking results, depending on your applications.

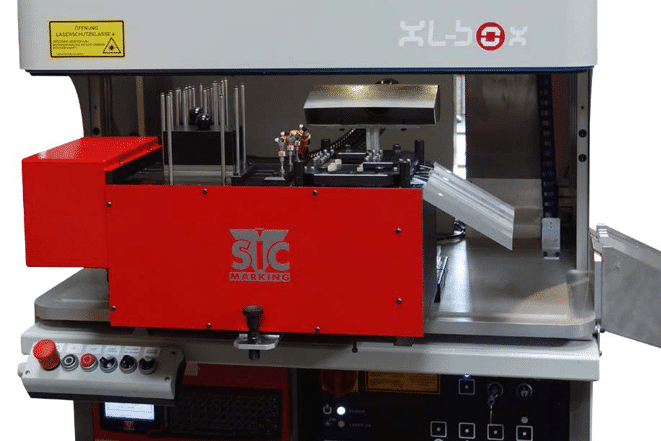

For particularly sensitive plastics (i.e. those that react strongly to lasers), our HD technology will be preferred.

For projects involving the marking of various types of plastic, that do not react to fibre laser, the green laser solution should be adopted.

Characteristics

Plastic is used everywhere today, because it is light, strong and very chemically resistant.

Plastic is mainly derived from refined oil and is created using several manufacturing methods.

It is mainly used in the automotive and energy sectors.

Depending on the laser wavelength, plastic reacts differently according to its type and the additives that it contains.

In order to obtain the best possible result (high contrast), the process changes the surface finish on the plastic material (colour change)

Laser experts use laser technology to define the source best suited to the need in relation to the material.

Laser technology is best suited to this material.

The LASER EASY range of SIC MARKING laser sources covers from 20 to 100W, including HD technology, and also the GREEN LASER which is very effective on plastics.

Laboratory tests are carried out free of charge by the experts of our Centres of Excellence, in order to accurately determine the ideal laser source.

Take a look at our case studies

Discover other materials

In addition to the conditions and requirements for marking a part, its inherent characteristics will determine the choice of the most suitable marking technology (laser, dot peen marking or scribing)

and the right marking machine (power, speed, portability, etc.).

The material, as well as the finish of the surface to be engraved, play a decisive role in making the right choice.

Contact us

Need information?

Contact one of our experts!