Stainless steel is one of the most used materials in industry.

Its anti-corrosion properties, its high strength and its attractive finish make stainless steel a preferred solution in terms of marking and traceability.

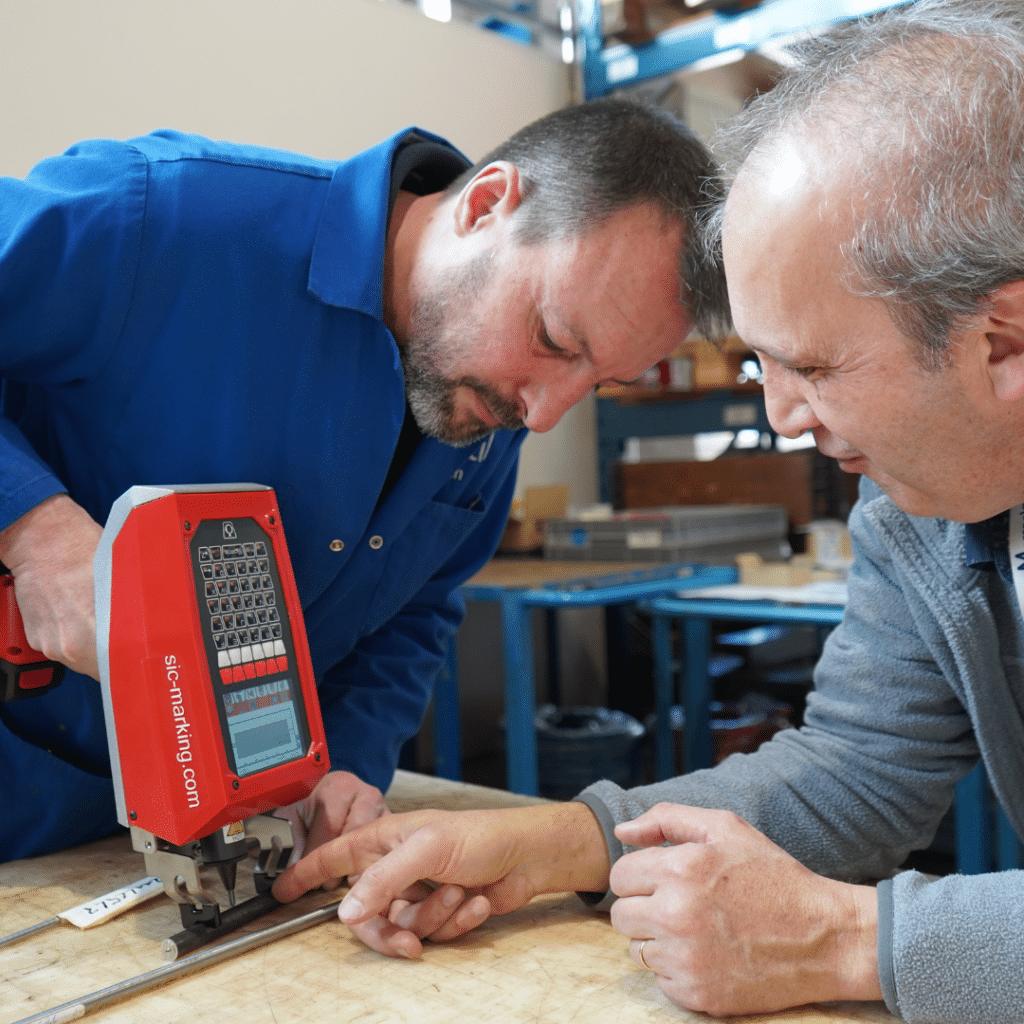

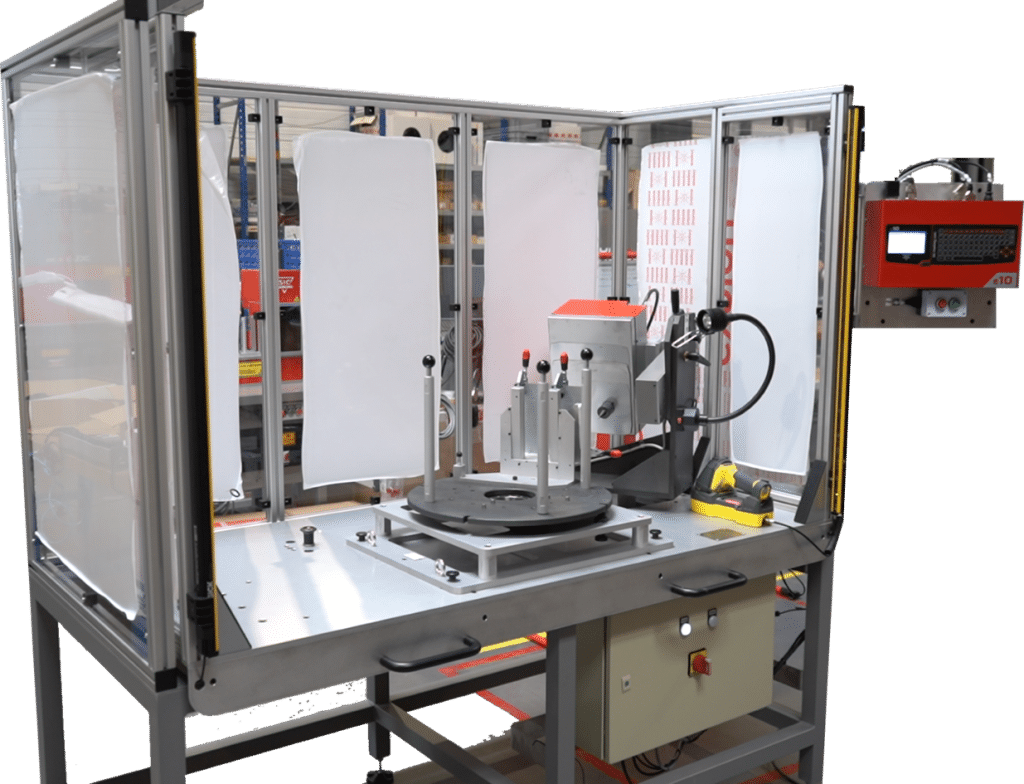

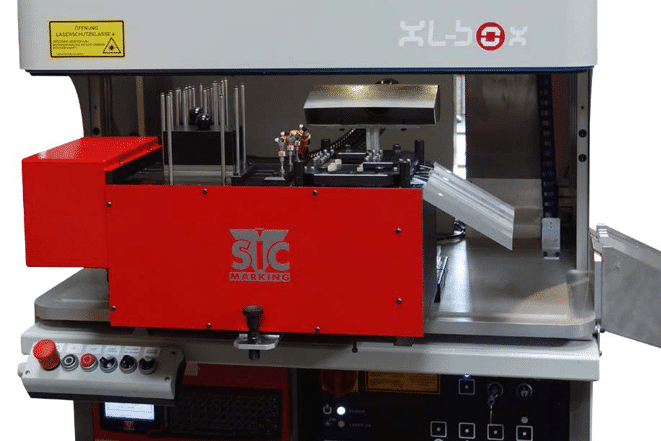

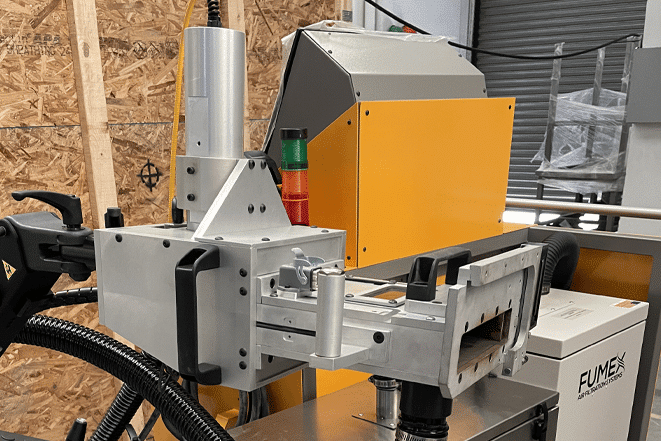

SIC MARKING engraving machines give high-quality results in laser technology, dot peen marking and scribing.

The anti-corrosion properties of STAINLESS STEEL and its high resistance to extreme conditions (temperatures), intense treatments (sterilisation, cleaning) and aggressive substances (acids) make it a very popular material for manufacturers.

It is used in major industrial sectors (automotive, aerospace, foodstuffs, consumer goods, medical, etc.).

STAINLESS STEEL gives particularly effective results in terms of marking and traceability. SIC MARKING engraving machines offer high-performance solutions that solve your field problems, in DOT PEEN MARKING, SCRIBING and LASER technology.

This alloy contains 50% iron, around 11% chromium and 1% carbon.

STAINLESS STEEL is rigid, strong, durable and versatile, and is used both indoors and outdoors.

Finish can be raw, machined or brushed.

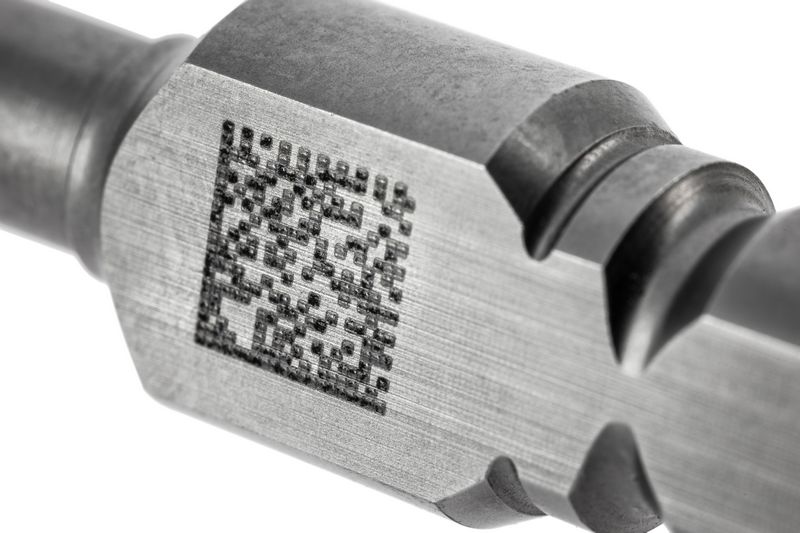

As for steel, SIC MARKING proposes a wide variety of types of marking on STAINLESS STEEL parts: light and precise marking, deep marking, marking by embossing (in relief), marking after treatment (thermal, coating, sandblasting, peening), marking in annealing (smooth marking preserving the surface condition)

Stainless steel can be marked using laser technology, dot peen marking or and scribing.

Laser engraving burns the metal using an infra-red beam.

Dot peen marking deforms the steel with a series of impacts by the carbide stylus.

Scribe marking uses a carbide spike that generates a groove in the steel surface.

Take a look at our case studies

Discover other materials

In addition to the conditions and requirements for marking a part, its inherent characteristics will determine the choice of the most suitable marking technology (laser, dot peen marking or scribing)

and the right marking machine (power, speed, portability, etc.).

The material, as well as the finish of the surface to be engraved, play a decisive role in making the right choice.

Contact us

Need information?

Contact one of our experts!