nos solutions > gamme atelier > stations laser

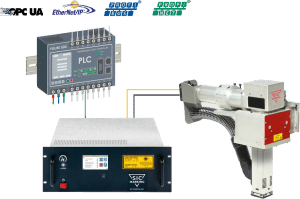

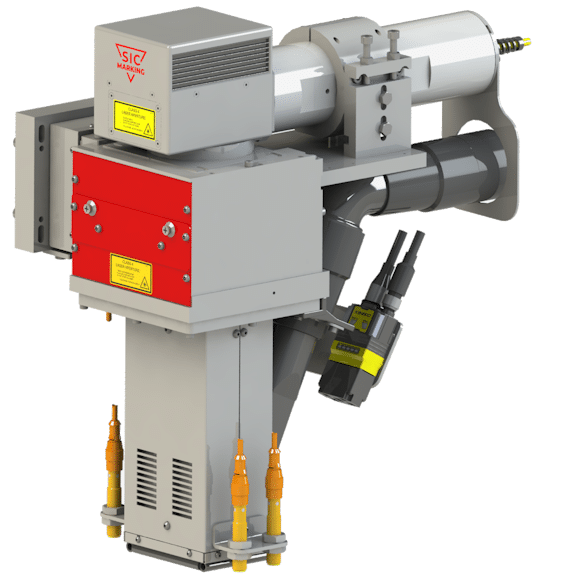

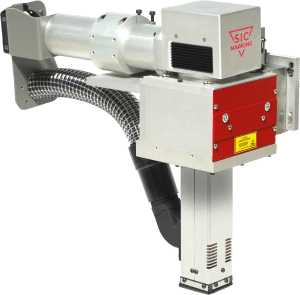

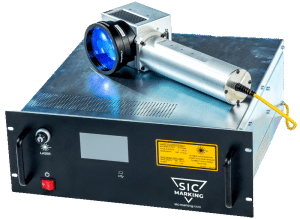

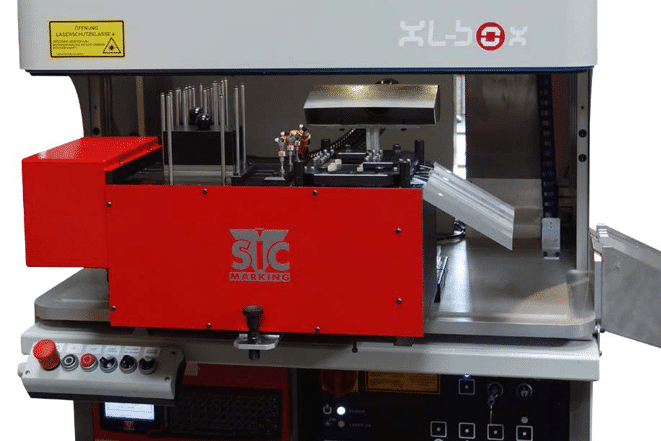

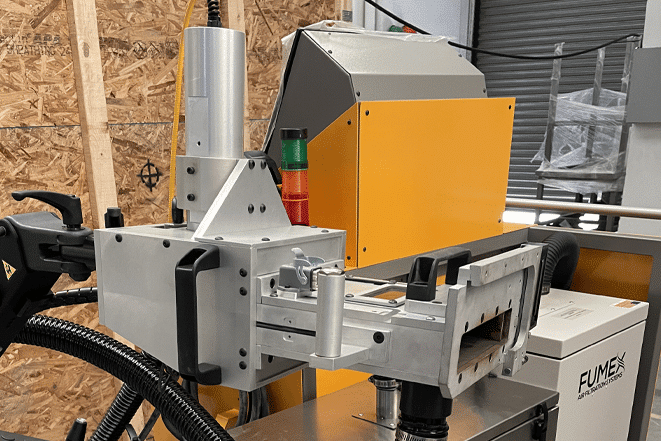

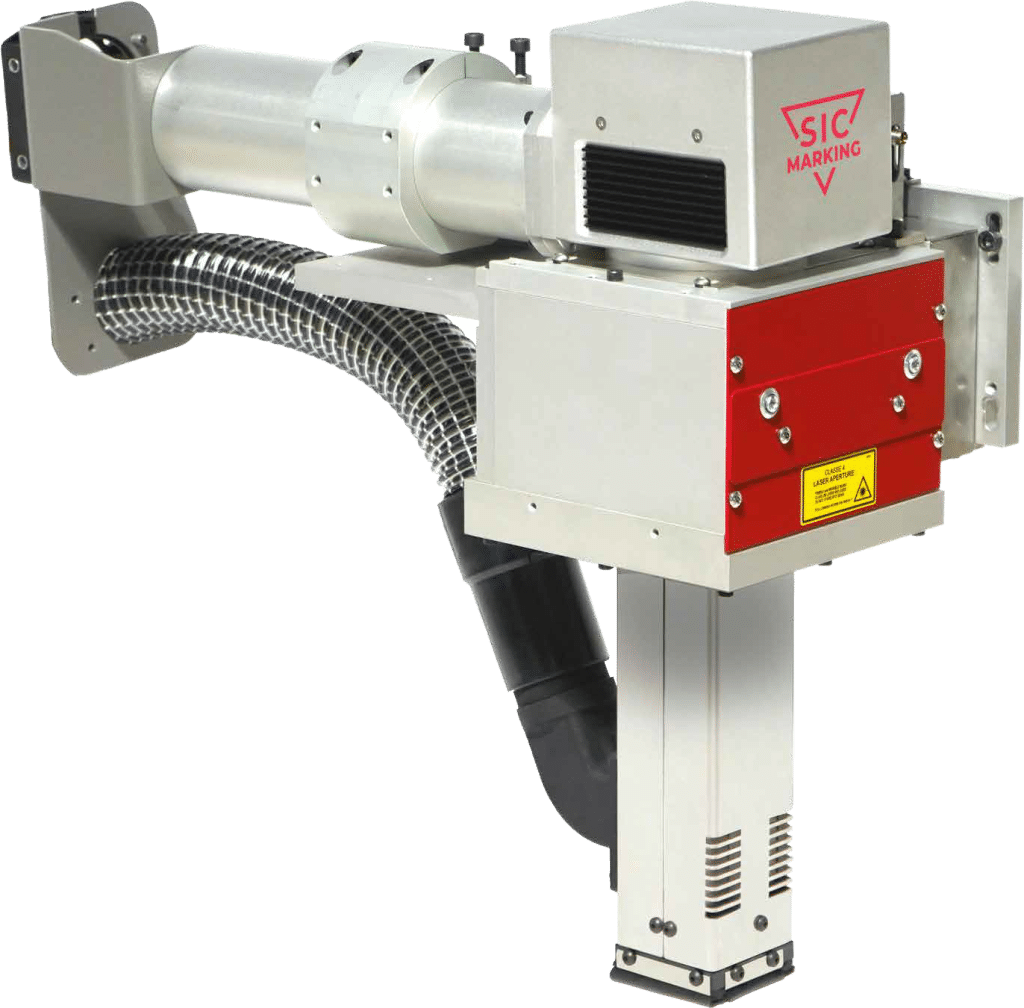

FIT LASER, a marking unit

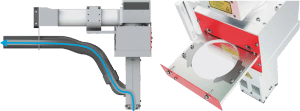

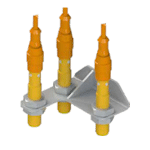

with safety funnel

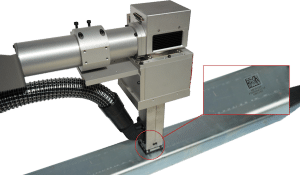

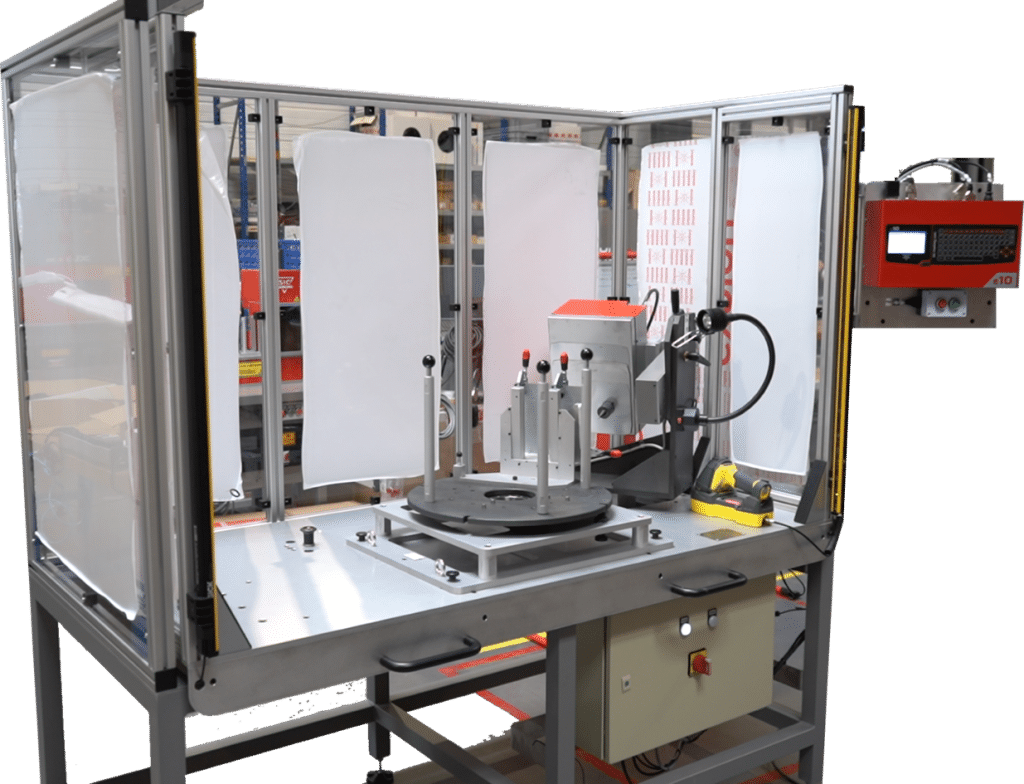

FIT LASER is an all-in-one integrated marking solution, containing all the protection you need for efficient, safe marking of your parts on the production line.

The FIT LASER marking system is designed for Class 1 integration, guaranteeing the protection of nearby personnel thanks to a beam enclosed in a radiation-tight sheath.

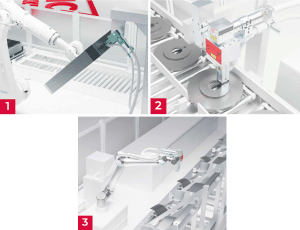

An integrated mechanical compensation system enables simple installation in your production.

It compensates for robot arm position deviations and part tolerance variations by up to 15mm.

It guarantees optimum laser focal distance and perfect marking quality.