our solutions > workshop range > LASER STATION

Laser marking station

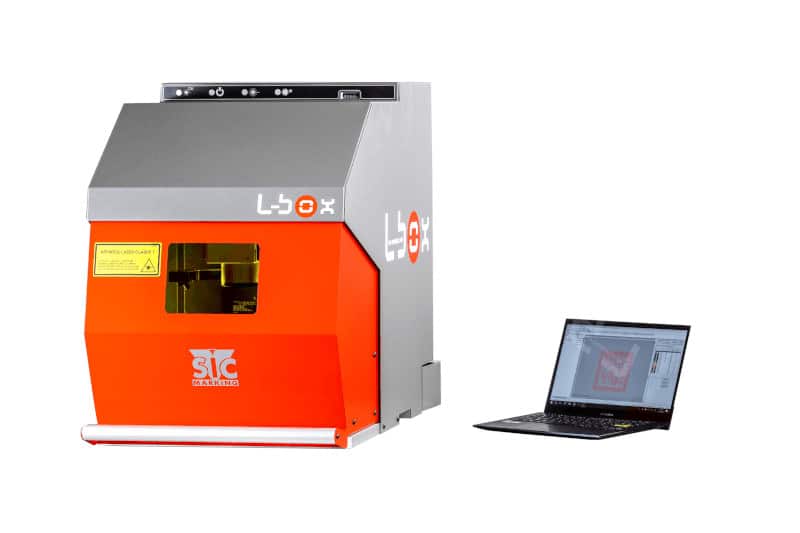

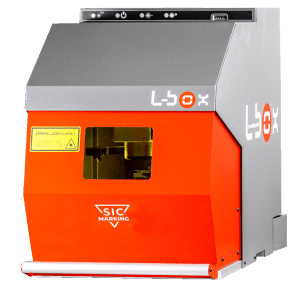

L-BOX

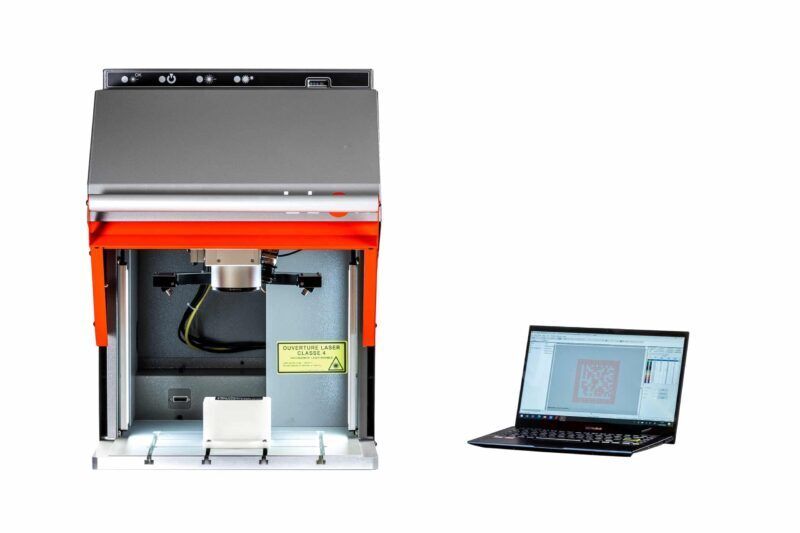

The L-BOX is a COMPLETE STANDALONE Laser marking station.

The ytterbium-enhanced SIC Marking fibre laser is a LATEST GENERATION TECHNOLOGY that enables high quality marking without affecting the material, irrespective of the material (steel, aluminium alloy, stainless steel, titanium, plastics, etc.) and with a shorter cycle time.

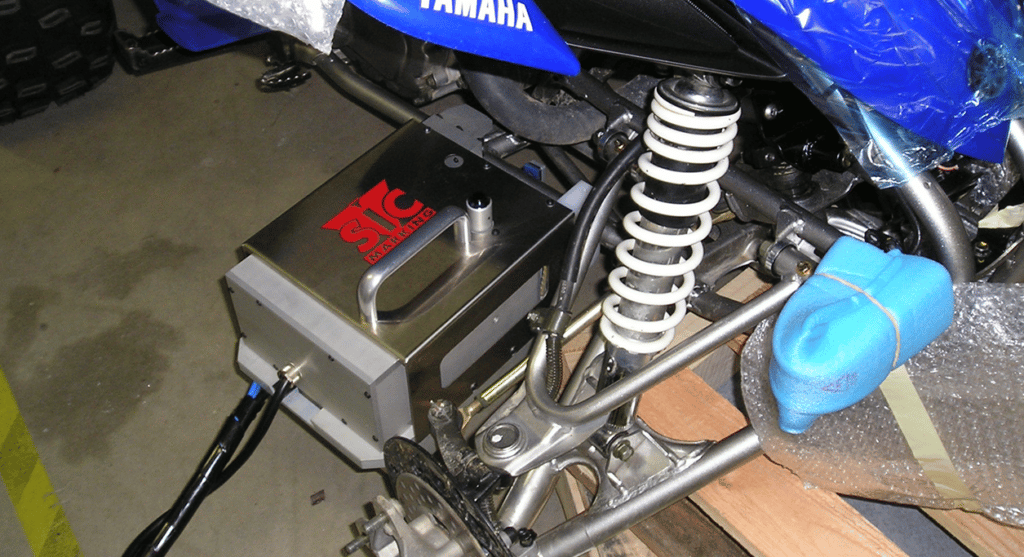

The L-BOX is a COMPACT Laser marking station that is easy to install on a table or bench, or can also be supplied with its chassis.

It is intended for industrial traceability and identification applications.

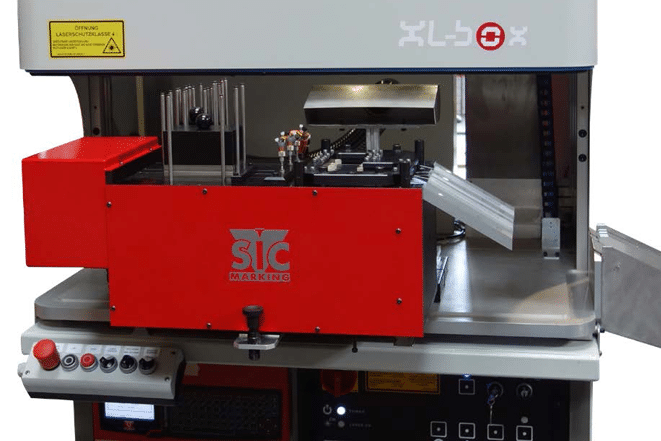

The station is designed to mark a broad variety of parts, for a low operating and maintenance cost. Its HEAVY DUTY COMPONENTS allow it to operate in any industrial environment.

Small, medium and even large production runs can be marked, as the L-BOX is designed for INTENSIVE AND MULTI-FUNCTION UTILISATION.

The L-BOX laser station is designed so that a user, even not very experienced in laser technology, can handle and operate it easily.

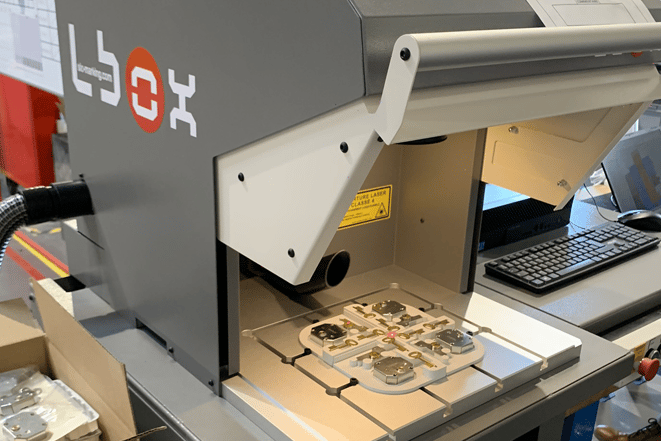

The manual door opens on 3 sides, which makes the loading and unloading of parts very easy.

In addition, the door opening and closing has a counterweight damping system for controlled and safe handling for the operator.

The station also has a COLUMN WITH A POSITION METER, for precise setting up and optimum marking.

The L-BOX equipment provides maximum safety during utilisation.

In addition to a CLASS 1 safety enclosure (standard EN 60825-1), the laser marking station L-BOX has a PL-E safety level, which is the highest possible according to standard ISO 13849-1.

The system status is indicated by LED lights in the top strip on the enclosure.

The interior of the work zone is lit up by LEDs, providing optimum working conditions for the user.

The L-BOX is available with castors and a table for a PC.

POSSIBLE OPTIONS TO ORDER

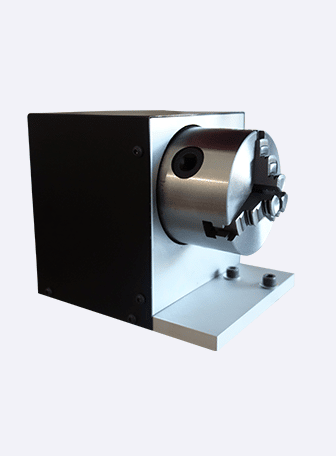

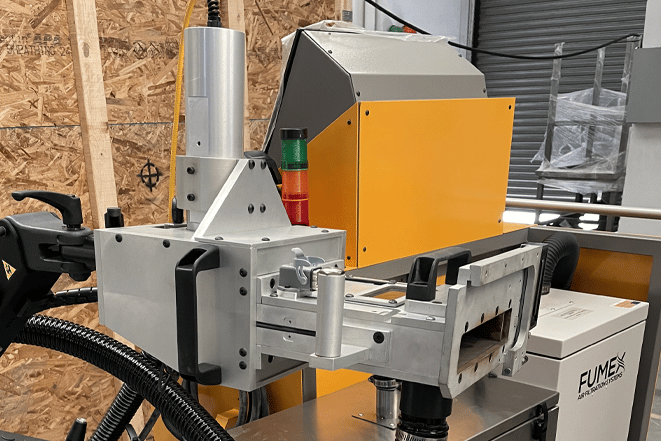

Different enclosure dimensions, creation of specific tools, supplementary movements (Z axis, rotary axis, automatic axis), etc. may be added, to meet your own needs.

3D marking (ability to mark one or more parts of different heights) or the integral reading system are also available as options.