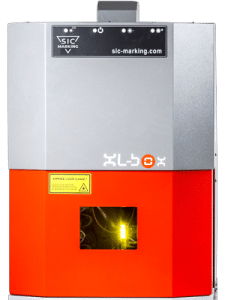

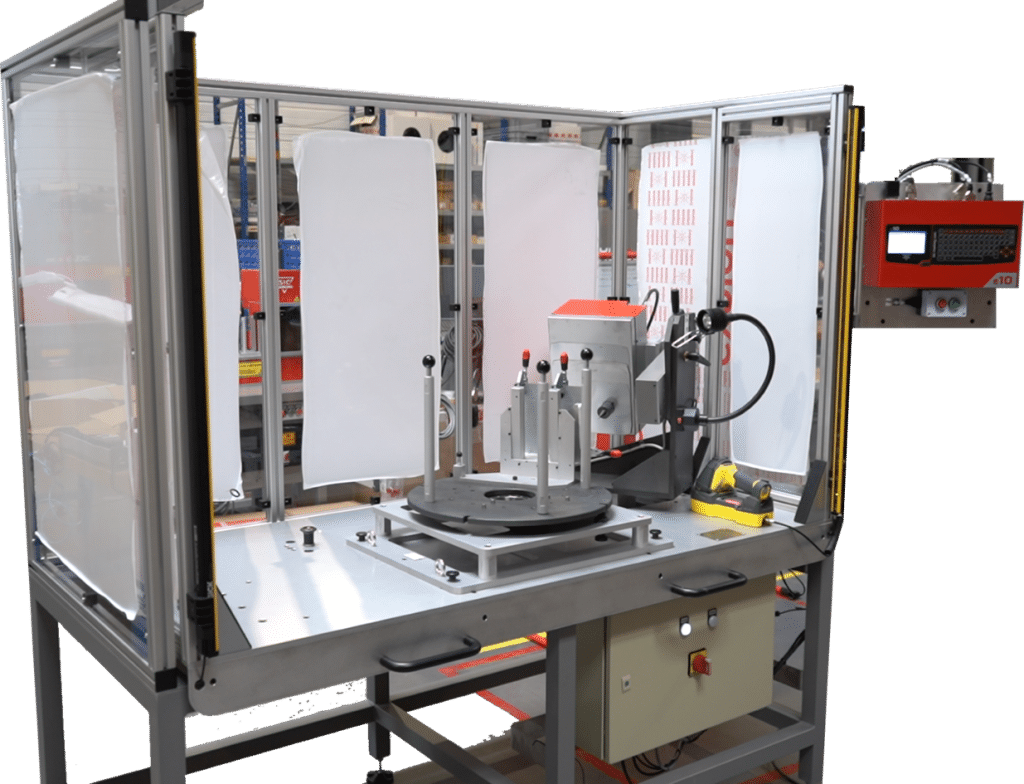

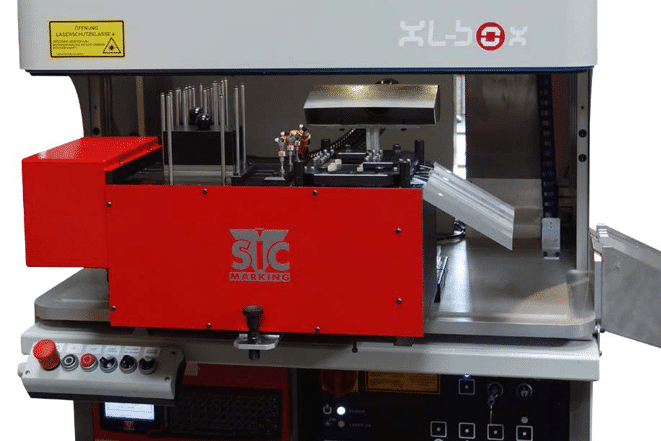

XXL-BOX laser station

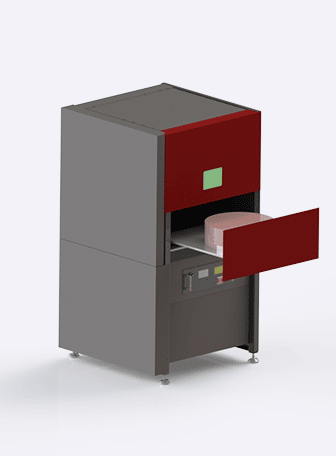

The XXL-BOX is a laser marking station designed to MARK particularly LARGE PARTS.

With a depth of 820 mm and the ability to mark parts up to 520 mm high, this station has THE GREATEST MARKING VOLUME ON THE MARKET.

The fibre laser used by this station is ytterbium-enhanced. This is a latest generation technology that enables HIGH QUALITY MARKING WITHOUT AFFECTING THE MATERIAL, irrespective of the material (steel, aluminium alloy, stainless steel, titanium, plastics, etc.) and with a shorter cycle time.

In order to meet the various needs, the XXL-BOX is available in 3 WIDTHS (800, 1200 or 1600 mm) and can be equipped with many standard or custom options, which makes it a particularly MODULABLE machine.

Used as a standalone station, the XXL-BOX is extremely ERGONOMIC for the operator, in particular due to easy access to a very large piece loading zone. The system status is indicated by LED lights in the top strip on the enclosure. The interior of the work zone is lit up by LEDs, providing optimum working conditions for the user.

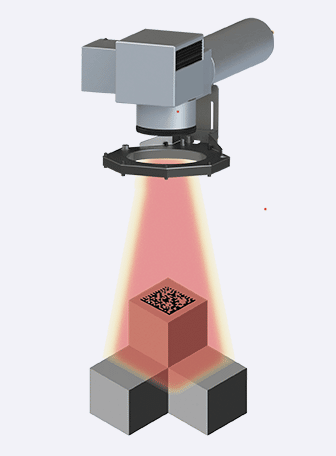

Optional MANUAL OR AUTOMATIC axes allow the LASER to be moved within the entire zone to mark parts.

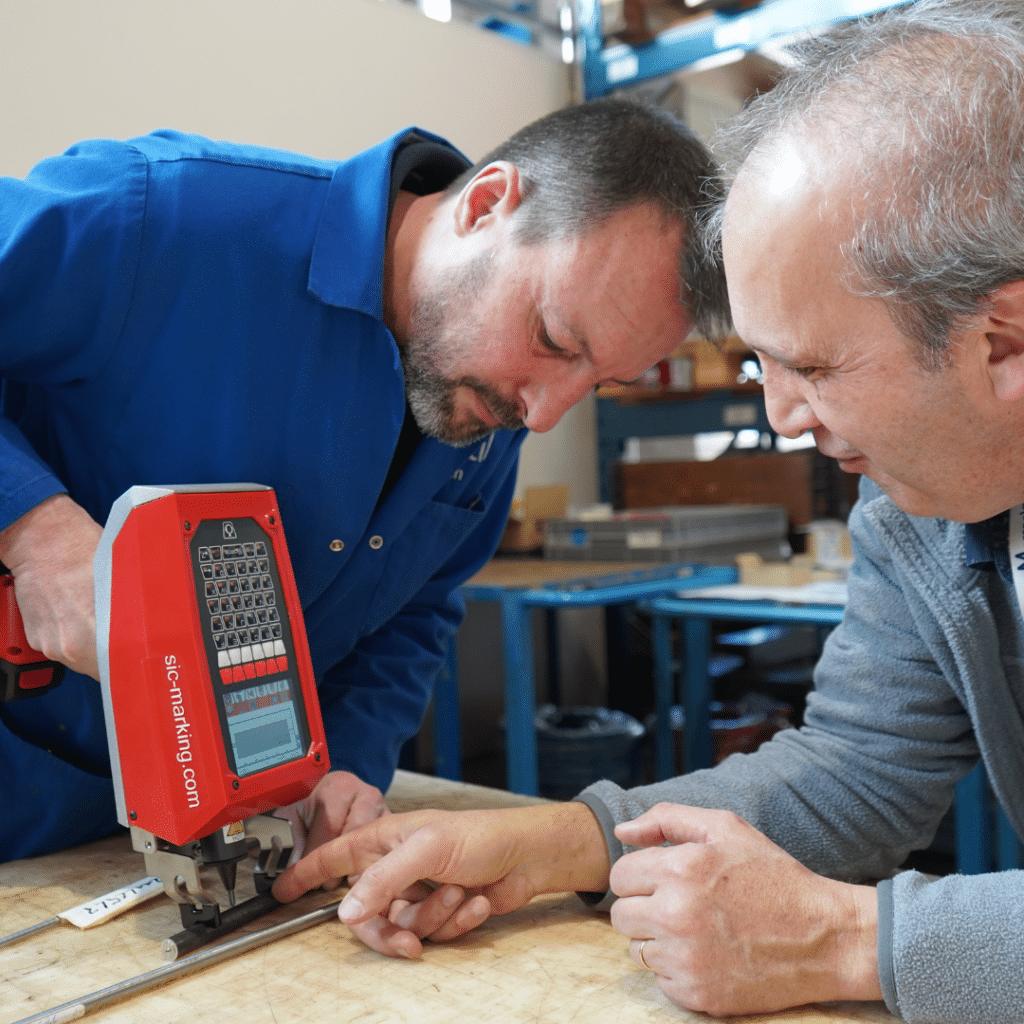

The UNIQUE AND INTUITIVE PRODUCTION SOFTWARE is easy to use, even for personnel without much experience in laser technology.

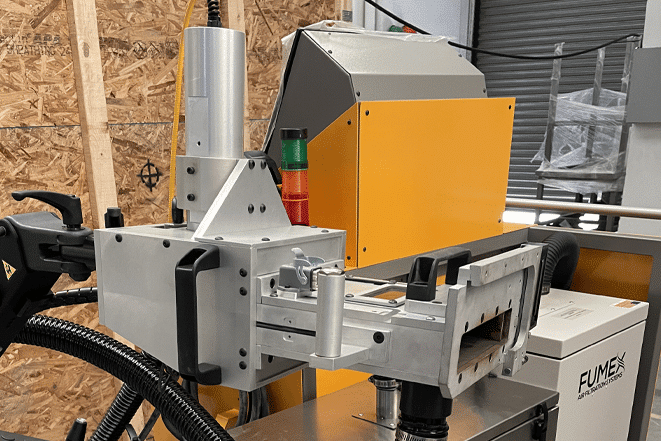

When the XXL-BOX laser marking machine is integrated into a robotised cell, ONLY ONE CONNECTION TO THE LASER CONTROL RACK is needed for the island PLC to manage the entire station.

The station can thus communicate marking data, open and close the automatic door to load and unload parts, start the marking or start up the fumes evacuation.

The XXL-BOX equipment provides MAXIMUM SAFETY during use.

In addition to a CLASS 1 safety enclosure (standard EN 60825-1), the laser XXL-BOX has a PL-E SAFETY LEVEL, WHICH IS THE HIGHEST POSSIBLE ACCORDING TO STANDARD ISO 13849-1.

The XXL-BOX provides high contrast engraving, readable with the naked eye, or instantaneously by reading cameras integral with the station.

The marking may be alphanumeric codes, barcodes or 2D Datamatrix codes.

The XXL-BOX is available with a table for a PC.