Dot peen marking or engraving makes it possible to generate permanent, tamper-proof and perennial markings on all types of parts and materials.

Dot peen marking or indented marking is widely used in the automotive industry, pioneering in its overall approach to quality via single component identification systems.

Today, it is present in most industrial sectors.

Our dot peen marking systems are designed to be installed in workshops, for fixed or mobile operation, or for integration into production lines.

The principle of dot peen marking involves striking the surface of the component or part to be marked with a tungsten carbide stylus.

Each impact generates a dot.

Thus, the stylus movement generates lines of dots in the form of numbers, codes, dates, logos, 2D codes, datamatrix.

The location, size and shape of the marking are predefined by the operator through ad hoc software.

SIC MARKING Precision Technology

SIC MARKING dot peen marking machines use electro-magnetic energy, thus ensuring extremely precise control of the series of impacts and excellent marking quality.

Pneumatic technology can also be used on certain installations requiring particularly high rates.

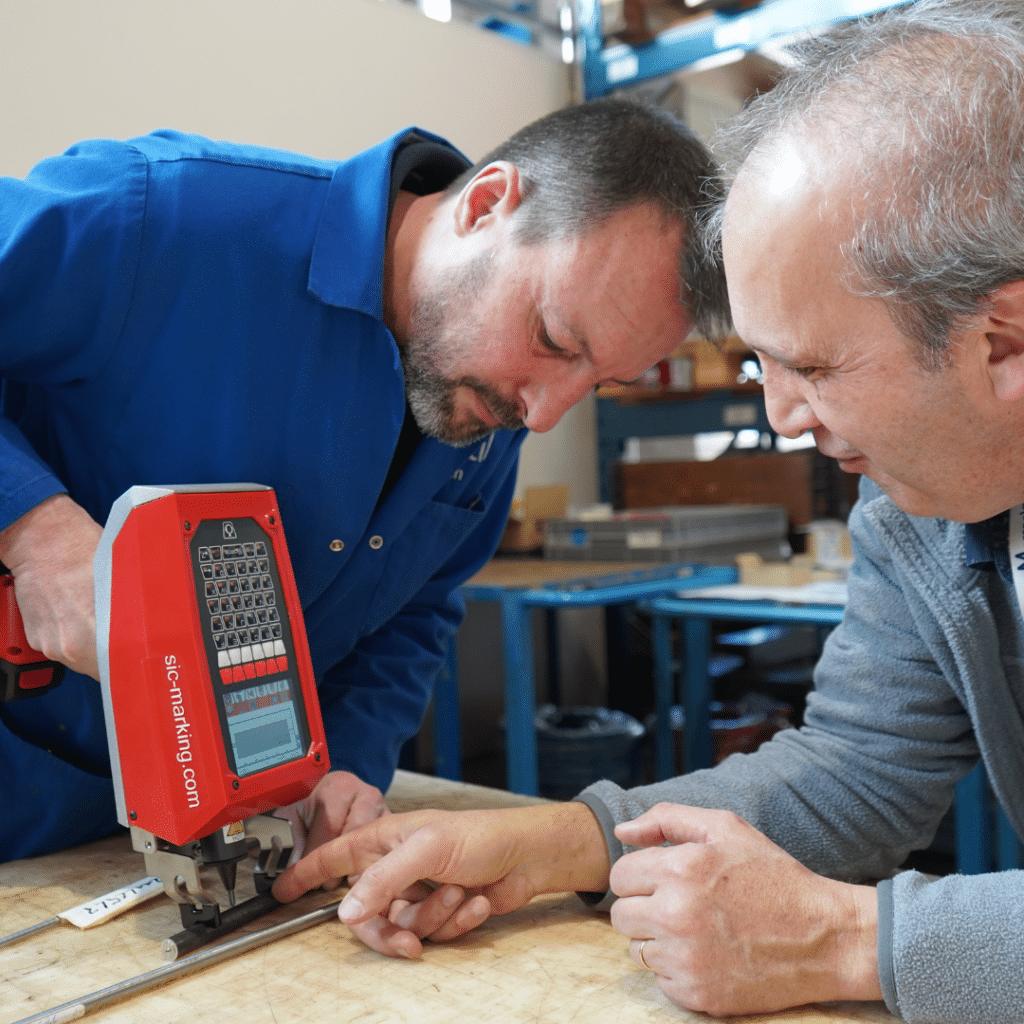

An expert’s opinion

Discover dot peen marking with our expert Christophe LASNIER

DOT PEEN MARKING technology

Principle

The precision and flexibility of this marking technology make it extremely versatile.

Depending on the material and type of marking required, the depth of the marking can be adjusted.

Micro-percussion marking is therefore possible on all metal and plastic parts, for light or very deep markings.

It can also be used to mark heavy, bulky parts that are difficult to access, raw or painted parts, as well as light or small parts.

DOT PEEN MARKING technology

Benefits

DOT PEEN MARKING technology

Solutions

We have a full range of dot peen marking systems, irrespective of the use and configuration of your industrial environment.

We thus offer three types of dot peen marking machine, depending on their use: mobile or fixed, integral or standalone.

Within a workshop: in mobile use, our portable machines (battery or cordless) allow easy movement of the operator to the parts to be marked.

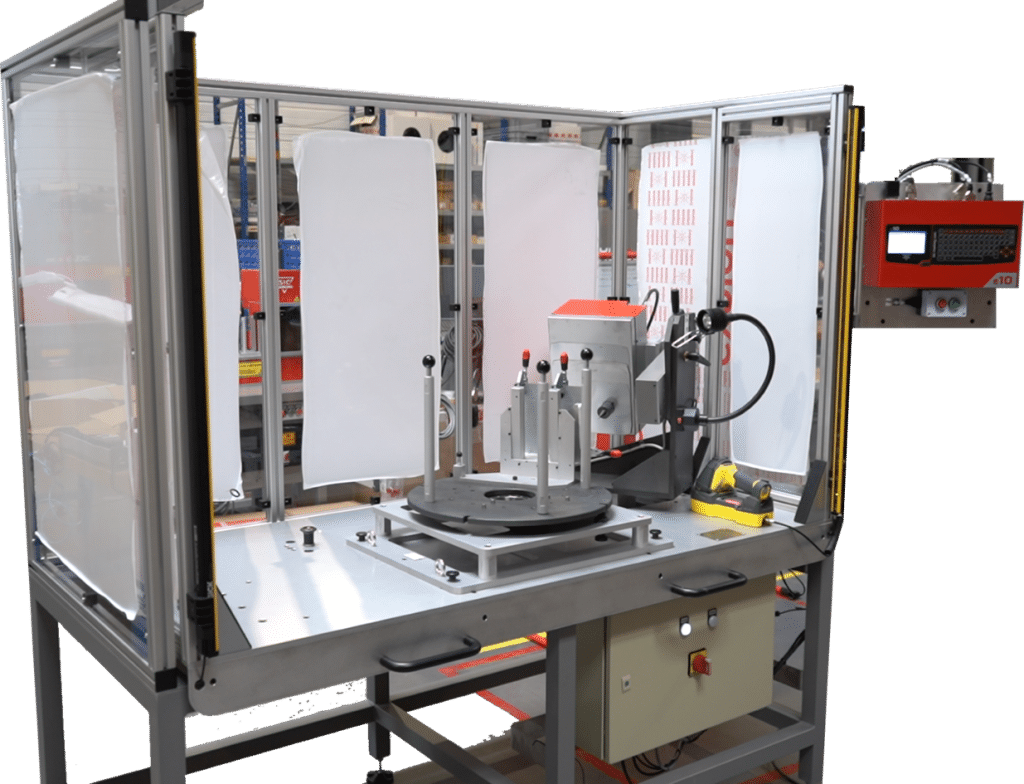

In fixed use if all the parts are engraved on the same workstation, our workbenches will stabilise and strengthen your marking process.

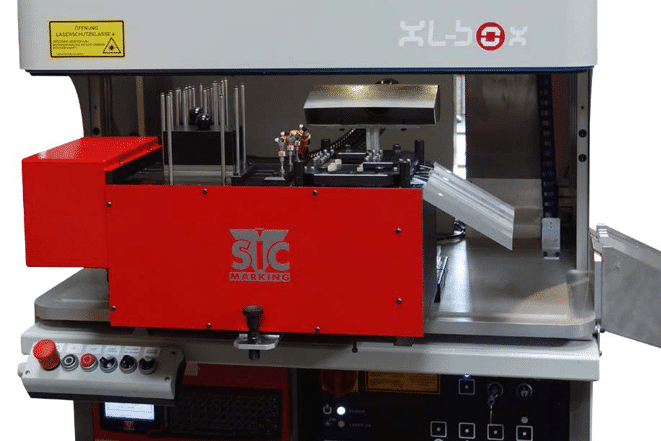

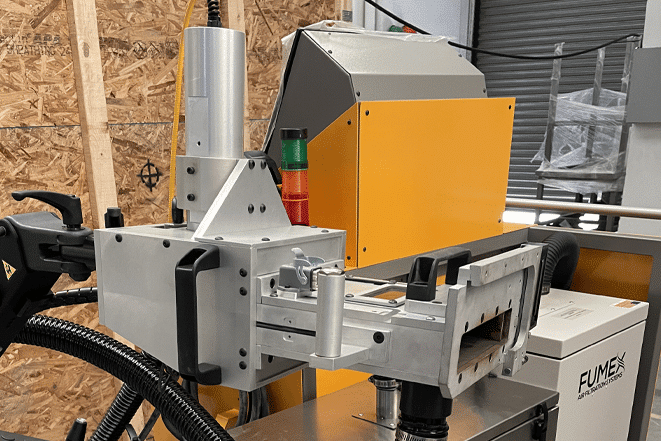

When incorporated in a production line, our integral solutions can be implemented quickly and easily due to their compactness and connectivity.

They trust us

Take a look at our case studies

Other technologies

With 30 years’ experience, we are experts in a number of marking technologies: Dot Peen marking, Laser marking and Scribe marking.

Our solutions are robust, technically advanced and tailored to our customers’ challenging industrial environments.

Contact us

Need information?

Contact one of our experts!