Product traceability is essential to meet the high quality requirements of industry.

For this reason, laser marking is used by manufacturers to automate marking operations and thus guarantee 100% control of their processes.

Laser marking technology is particularly used for direct and permanent marking of metal or plastic parts depending on the hardness and their surface condition.

Industrial laser marking is recommended for mass production, where speed and accuracy are required.

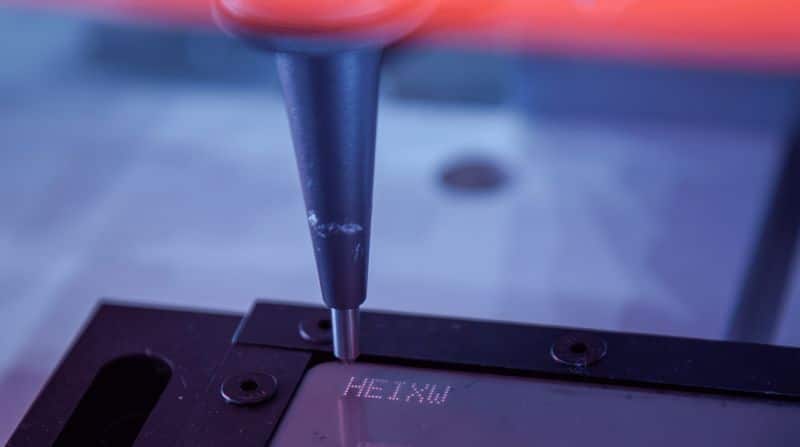

LASER MARKING TECHNOLOGY emits radiation from a source, amplifies it and directs it, via mirrors, onto the part to be marked.

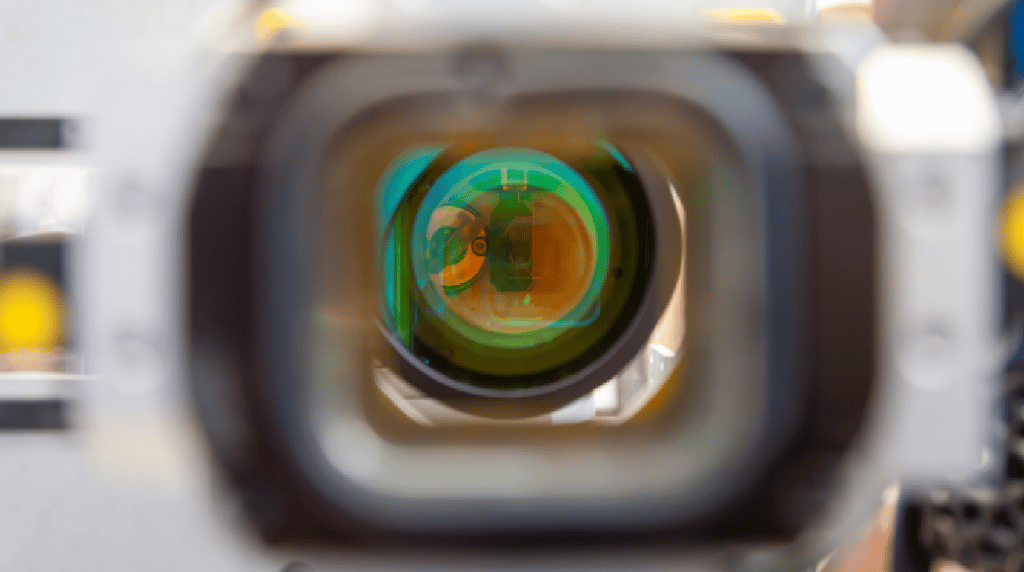

The beam is amplified through optical fibre and then directed along 2 axes via the mirror galvanometer head which contains 2 mirrors.

The focusing lens, at the tip, concentrates all the power on a single point.

The beam creates a THERMAL REACTION in contact with the material, which causes the marking.

SIC MARKING adopted an Ytterbium-enhanced FIBRE LASER SOURCE for reliability, power, versatility and low operating costs.

An expert’s opinion

Discover laser marking with our expert Benoit MASSEL

LASER TECHNOLOGY

Principle

Laser engraving is mainly used for direct and permanent marking on all types of material, from plastic to metal parts, irrespective of their hardness and surface condition.

Our laser engraving machines can mark all alphanumeric characters, logos, 1D and 2D standard codes (datamatrix, QR code…) with precision and contrast.

The laser is recommended for applications with high rates and an important marking requirement.

Depending on your needs, you can add options such as 3D marking or integral reading systems at any time.

We can adapt all our laser marking machines to your particular specifications.

LASER TECHNOLOGY

Benefits

LASER TECHNOLOGY

We offer two types of laser engraving machine: integral laser marking systems and standalone laser marking stations.

Our integral industrial lasers are designed to mark at high rates with an extremely low operating and maintenance cost.

These robust machines can mark all alphanumeric characters, logos, 1D and 2D standard codes, with precision and contrast.

Integration is facilitated by the compact marking head.

Our integrated laser connectors are compatible with industrial communication standards: PROFINET, Profibus, Ethernet IP, etc.

Our standalone laser marking stations are designed to increase marking station productivity in complete safety.

The choice of station depends on workstation ergonomics (manual or automatic), production rate and the size of the parts being marked.

All are equipped with a simple and user-friendly human-machine interface, compatible with various user profiles, for one-off or series markings via a database.

Various options are available to meet your specific needs.

The solution you adopt will be upgradable and can be upgraded with new options according to new specifications or applications.

The major features of the SIC MARKING Laser offer are its modularity and its value for money.

For any specific request, our design department can develop a custom solution for you.

They trust us

Other technologies

With 30 years’ experience, we are experts in a number of marking technologies: Dot Peen marking, Laser marking and Scribe marking.

Our solutions are robust, technically advanced and tailored to our customers’ challenging industrial environments.

Need information?

Contact one of our experts!