The future of industrial marking: trends and predictions

Key trends in industrial marking

- Expansion of IoT in industrial marking:

The IoT is transforming traceability processes in all industries. In the near future, marking machines are expected to be fully integrated into smart networks, enabling real-time collection and analysis of critical data.

For example, laser-engraved DataMatrix codes, already a standard tool for traceability, will evolve to be integrated into IoT systems. In this way, each part or product will be able to communicate with the supply chain, providing instant information on its origin, status and destination.

- Sustainability at the core:

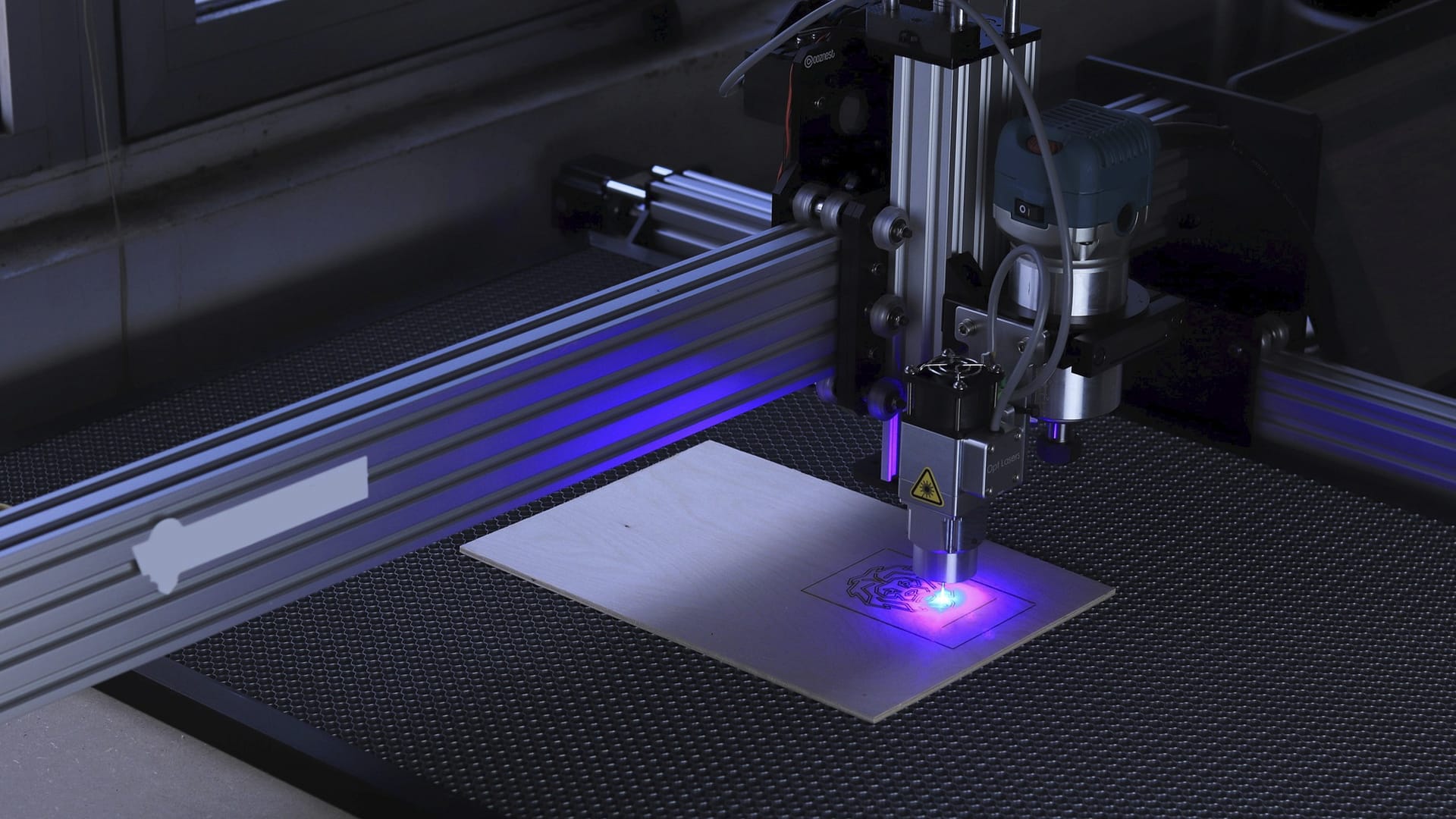

Sustainability is a growing priority for companies, and industrial marking is no exception. Technologies such as laser marking are more sustainable than traditional methods such as ink or adhesive labeling, as they eliminate waste and reduce resource consumption.

In the future, marking systems will have to comply with stricter sustainability regulations. In addition, traceability of recyclable materials will be essential to ensure an efficient circular economy. SIC Marking is already working on solutions to identify materials and ensure their reuse in recycling processes.

- Automation and artificial intelligence (AI):

Automation and AI are leading the way to a more efficient and flexible industry. In the field of industrial marking, this translates into systems that can automatically adjust parameters such as laser intensity, focus and marking design based on material or product geometry.

In the future, marking systems will not only become more autonomous, but will also be connected to intelligent production management platforms. This will make it possible to predict failures, optimize production times and customize products in real time, in response to customer demands.

Impact on different sectors

The impact of these trends will be evident in a variety of industries:

- AutomotiveWith full traceability of each component, manufacturers will be able to manage recalls more efficiently and improve transparency in their supply chains.

- AerospaceLaser marking precision will be essential to meet stringent quality and safety standards.

- HealthcareMedical device marking will benefit from advances in IoT and sustainability, ensuring regulatory compliance and reducing environmental impact.

- ElectronicsMass customization: manufacturers will be able to take advantage of mass customization to meet the demand for products tailored to consumer needs.

SIC Marking drives business transformation

The future of industrial marking is defined by digitalization, sustainability and customization. These trends not only improve operational efficiency, but also enable companies to comply with increasingly stringent regulations and meet customer expectations.

With innovative technologies and a focus on adapting to change, SIC Marking is positioned as a key partner for companies looking to lead in a dynamic and constantly evolving industrial environment. Now is the time to invest in solutions that not only solve today’s needs, but also prepare companies for tomorrow’s challenges.